The GF Automatic Cans Tin Capping device is simply a must-have for almost any manufacturing food or plant processing center. This machine that is innovative built to improve efficiency in sealing tin cans in just a matter of seconds. The capping machine was created to meet up with the quality standards and that can be highest, and it is made from durable materials that will withstand regular use.

As a result of the technology that is advanced machine can fit and seal tin cans of different sizes. The ability is had due to it to seal cans with diameters ranging between 50-180mm, that makes it perfect for use in various production lines. Also, this machine is adjustable, this means it may be customized to meet manufacturing this is certainly specific.

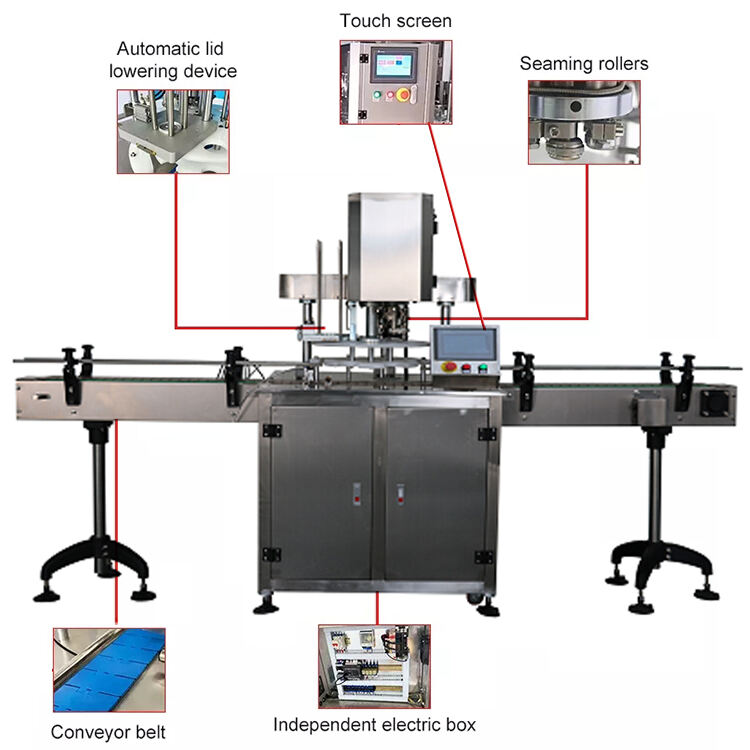

The GF Automatic Cans Tin Capping Machine is user-friendly and easy to use. It's fashioned with a user this is certainly clear, along with its functions could be controlled with only a sense. The machine has a conveyor system that effortlessly transports cans to the sealing location. When the cans come in position, its sealing heads take over and seal the cans with minimal intervention that is human being.

The equipment possesses output this is certainly high and will seal as much as 2400 cans each hour. Which means it might seamlessly incorporate with existing manufacturing lines without slowing the technique this is certainly whole. It eliminates the need for handbook sealing by employees, reducing the odds of human safety and error this is certainly improving the production line.

Furthermore, this machine is made having a design this is certainly easy enhance ease of upkeep. Its modular elements can be replaceable, reducing downtime when repairs are necessary. The GF Automatic Cans Tin Capping device can additionally be energy-efficient, meaning it uses less power while doing tasks which are complex.

Item |

Parameters |

Model |

GFCYT-1 |

No. of sealing heads |

1 |

Sealing speed |

30~35cans/min |

Sealing height |

60~200mm |

Sealing diameter |

Φ40- Φ130mm |

Control Mode |

PLC and touch screen |

Total Power |

1.3Kw |

Machine Overall size (L*W*H) |

3000*900*1800mm |

Packing size (L*W*H) |

1350*1200*1900mm |

Net Weight |

About 500Kg |

Gross Weight |

About 550Kg |

Material |

SUS304 stainless steel |

Conveyor belt |

L:3000mm long, H:900mm,Chain width: 114mm; |

Conveyor motor |

0.2Kw |

Main motor power |

1.1Kw |

Voltage |

220V,50/60Hz Single Phase |

1. |

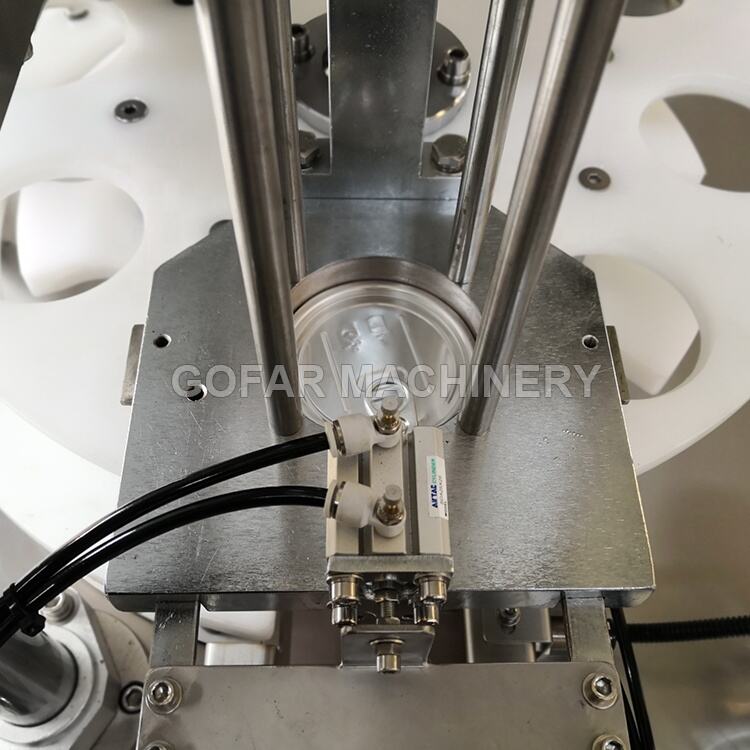

Whole machine servo control makes the equipment run safer, more stable and smarter. speed can be adjusted separately; When there is a foreign object stuck in the turntable, it will automatically stop running to prevent artificial Equipment damage and safety accidents caused by incorrect operation of the equipment.After one button reset,the error can be released and machine restart to run |

2. |

Adopt 4 hobs for sealing, the sealing force is more uniform, and the sealing performance index can reach international standards |

3. |

The can body does not rotate during the sealing process,which is safer and is especially suitable for fragile and liquid products. |

4. |

For the company's 7th generation products, there are more than 3,500 customers of the same product using the feedback experience,and the failure rate is extremely low; |

5. |

Applicable to tin cans, aluminum cans, plastic cans and paper cans. it is the ideal packaging equipment for food,beverage. |

6. |

Maintenance instructions are posted on the side of the fuselage, and maintenance operations are simple and convenient. |