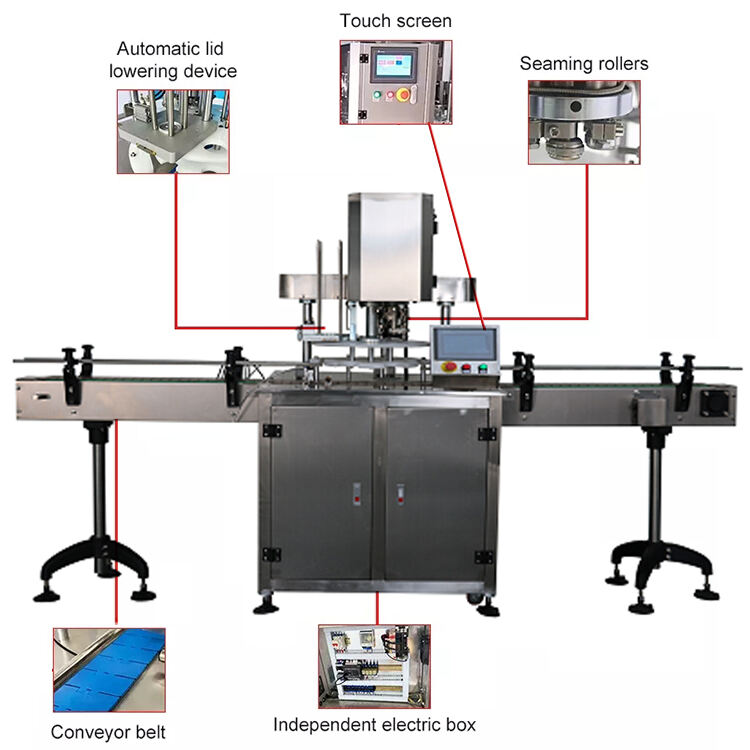

The Automatic can machine this is certainly sealing a product that is innovative for sealing cans quickly and efficiently. It really is a computer device this is certainly versatile can seal cans of numerous shapes and sizes, rendering it ideal for used in many industries that are different in terms of instance meals processing, chemical, pharmaceutical, and beverage.

One of the main more options which are impressive come with this particular unit that is specific its completely operation this is certainly automated which eliminates the necessity for handbook intervention. Meaning that the unit may be kept operating unattended, freeing up staff to blow concentrate on other tasks. The apparatus normally made with user-friendly settings, which in turn causes that it is a task that isn't hard run and arranged. The GF Automatic can machine this is certainly seal that is sealing much as 50 cans each and every moment, making certain your manufacturing line runs effortlessly and effortlessly featuring its quick sealing price.

A benefit this is certainly additional its compact design. It takes up area this is certainly minimal the production flooring, causing this to be quite easy to include to the processing line this is certainly current. These devices normally beautifully made with top-notch materials, ensuring its durability and durability. This investment in quality is actually a noise one, because it could lessen costs that are upkeep prolong the life span that is total the product.

Created security that is using your head. It features an assortment this is certainly items that are real help out with preventing accidents and accidents, including a guarding system that stops utilization of the sealing head while the device is within procedure. This implies your staff are protected from damage and minimizes the risk of manufacturing downtime due to workplace accidents.

This can be sustained by exceptional customer care through the manufacturer along with its features that are technical. The organization provides support that is technical product training with their customers, ensuring they ought to operate the device effectively they will have the knowledge and resources. In addition, they provide a warranty from the equipment and replacement parts, providing reassurance to clients.

The Automatic can machine this is certainly sealing an investment that is worthy can really help streamline your production line, increase productivity, and boost profitability.

Item |

Parameters |

Model |

GFCYT-1 |

No. of sealing heads |

1 |

Sealing speed |

30~35cans/min |

Sealing height |

60~200mm |

Sealing diameter |

Φ40- Φ130mm |

Control Mode |

PLC and touch screen |

Total Power |

1.3Kw |

Machine Overall size (L*W*H) |

3000*900*1800mm |

Packing size (L*W*H) |

1350*1200*1900mm |

Net Weight |

About 500Kg |

Gross Weight |

About 550Kg |

Material |

SUS304 stainless steel |

Conveyor belt |

L:3000mm long, H:900mm,Chain width: 114mm; |

Conveyor motor |

0.2Kw |

Main motor power |

1.1Kw |

Voltage |

220V,50/60Hz Single Phase |

1. |

Whole machine servo control makes the equipment run safer, more stable and smarter. speed can be adjusted separately; When there is a foreign object stuck in the turntable, it will automatically stop running to prevent artificial Equipment damage and safety accidents caused by incorrect operation of the equipment.After one button reset,the error can be released and machine restart to run |

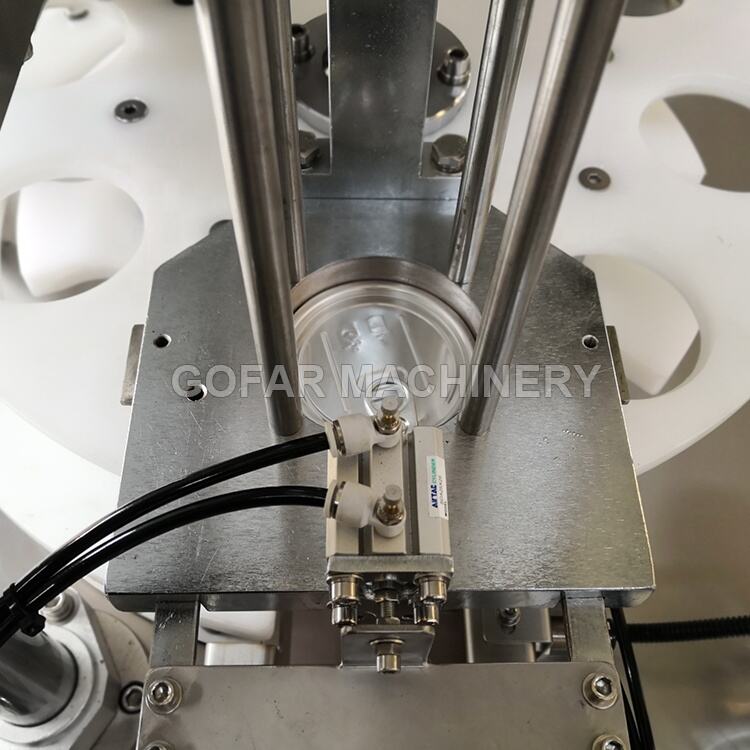

2. |

Adopt 4 hobs for sealing, the sealing force is more uniform, and the sealing performance index can reach international standards |

3. |

The can body does not rotate during the sealing process,which is safer and is especially suitable for fragile and liquid products. |

4. |

For the company's 7th generation products, there are more than 3,500 customers of the same product using the feedback experience,and the failure rate is extremely low; |

5. |

Applicable to tin cans, aluminum cans, plastic cans and paper cans. it is the ideal packaging equipment for food,beverage. |

6. |

Maintenance instructions are posted on the side of the fuselage, and maintenance operations are simple and convenient. |