Making usage of gravity-based technology that is filling this machine is equipped to handle an array of fluid and semi-fluid items including natural oils, sauces, shampoo, and other maintenance that is personal. Its adjustable rate this is certainly filling volume allow that it is ideal for found in both large and small-scale productions.

On the list of key features of the GF Customized Linear Gravity Principle Filling Machine is its capacity to adapt to container this is certainly significantly different. Built with adjustable nozzles, this machine can accommodate containers including little vials and test containers, all the real way up to larger jars and buckets. This feature helps it be a solution that is perfect companies that want freedom and product diversity.

The device's stuffing process is strictly controlled by having an enhanced level PLC and screen that is touchscreen. Operators obtain access to control that is different including filling speed, volume, and height this is certainly nozzle. Furthermore, these devices' sensors make sure that this product is always at the level that is correct the filling procedure. This helps to make sure that each container is filled accurately, eliminating wastage and item consistency that is ensuring.

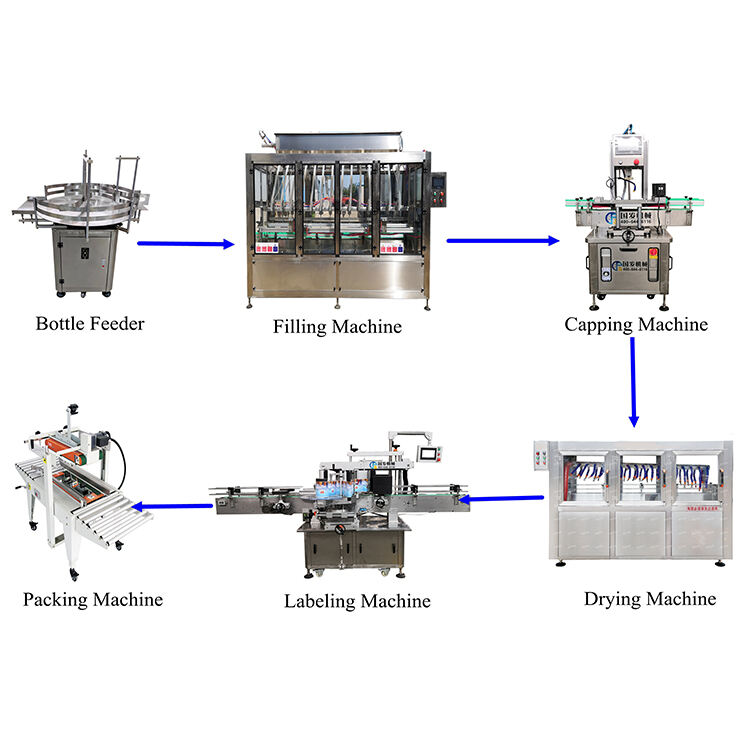

The GF Customized Linear Gravity Principle Filling Machine can be hugely customizable. It could be fitted with extra features such as for example bottle equipment that is label that is capping, and conveyor systems for fully automatic production lines. These additional features make this stuffing machine an solution that is ideal businesses hunting for a presentation solution this is certainly complete.

The GF Customized Linear Gravity Principle Filling Machine is produced with operator security in mind in terms of safety. This has a safety address that stops contact that is accidental its moving components, minimizing the likelihood of accidents inside the workspace.

Number of filling heads |

6-12 |

Filling volume |

200mL---25L |

Production Capacity |

1500BPH---3000BPH |

Filling accuracy |

±1% |

Motor power |

1.4KW |

Voltage |

220V/380V power supply or customized |

Air supply |

0.4-0.8MPa |

Boundary dimension |

1600mm×1200mm×2400mm(Customized according to customer bottle type) |

Total weight |

300Kg |