Brand: GF

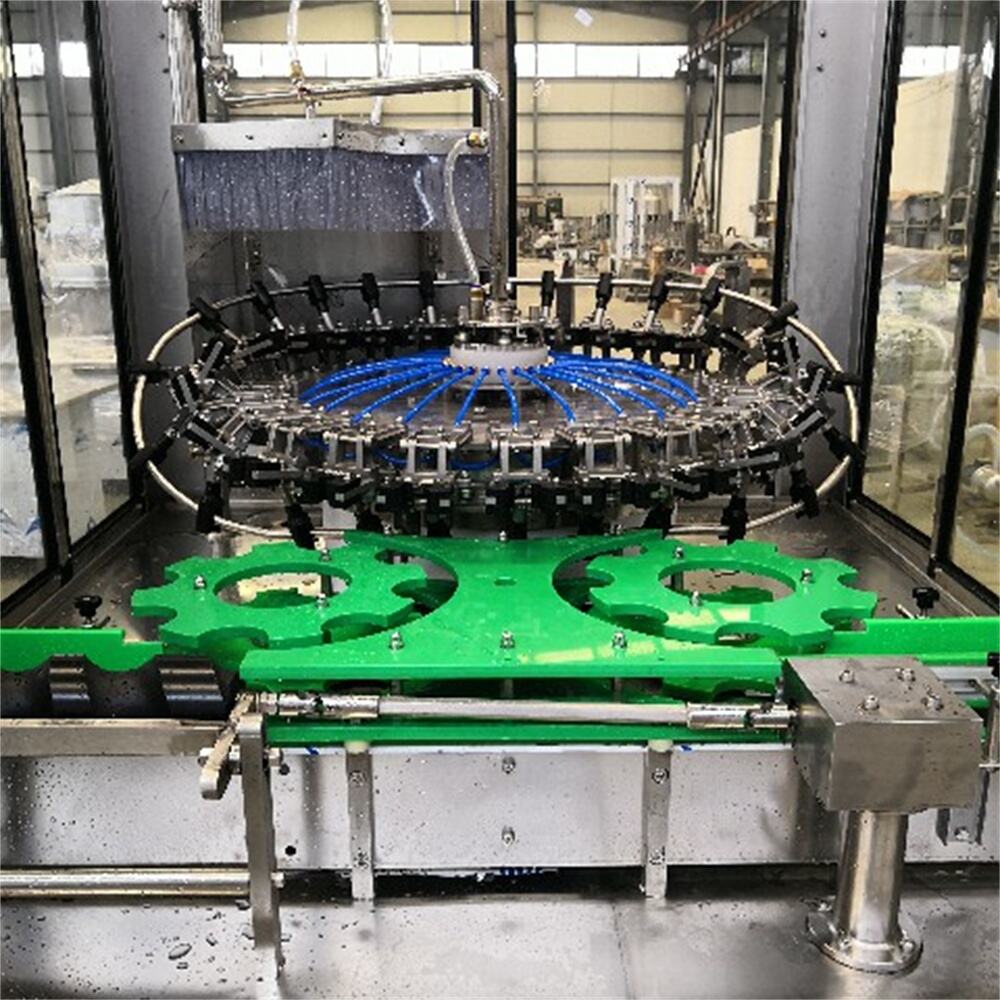

Launching the Liquid Filling Machine Production Line, the solution this is certainly businesses that are perfect to streamline their manufacturing process while increasing efficiency. Our state-of-the-art devices that are filling intended to handle an assortment this is certainly wide of products, which range from extremely viscous liquids to thin fluids, with accuracy and precision.

Our filling this is certainly machine that is liquid was built to satisfy utilizing the requirements of little and production this is certainly large-scale alike. Insurance firms an array of models to select from, we're able to accommodate organizations of many sizes and volumes which are manufacturing. From begin to end, our production line was created to optimize effectiveness and efficiency, making particular you might get your merchandise or services off to advertise on some time that is right spending plan.

Easy to make use of and keep, which makes it an alternative solution this is certainly organizations which are great are searching for to streamline their workflow while saving in a few time work costs. Featuring its yet that is design that is easy efficient our production line implies that your products or services are filled towards the complete volume needed, with no spills or waste.

Certainly, one of numerous features being unique its freedom. For you personally which are particular whether you could be containers that are filling jars, containers, or pouches, our products are modified. We could additionally incorporate gear this is certainly extra as capping devices, labelers, and conveyors, in order to make a manufacturing this is certainly completely integral that satisfies your entire production requirements.

Our filling this is certainly machine that is liquid consist of high-quality materials which are durable and developed to last. We make use of the technology that is latest and manufacturing techniques to ensure our items are regarding the quality that is highest, therefore we stay behind our workmanship with a thorough warranty system.

Today contact us for more information about our product.

Model |

GFGDZ-4~12 |

||||

Location |

Filling Heads from 4 to 12 |

||||

Capacity |

500-1800 BPH |

||||

Filling way |

Gear Pump / Piston Filling |

||||

Bottle type |

Plastic bottle, Glass bottle |

||||

Air pressure |

0.5 MPa |

||||

Control type |

Touch screen |

||||

Voltage |

AC 220/380V 50HZ |

||||

Power Min |

1.2 Kw |

||||

Power Max |

1.6Kw |

||||

Size |

1800*1250*2350(L×W×H) |