Searching for a reliable and easy-to-use dental liquid machine that is filling? Look no further than GF's automated Stainless Steel Oral Liquid Filling Machine.

This machine that is high-quality well suited for companies and manufacturers whom need to fill fluid medications, supplements, vitamins, along with other dental liquid products quickly and accurately. This product is developed to last and offer consistent results every time with higher level technology and metal construction that is durable.

By having an filling that is automatic, it is simple to set the amount of liquid you will need to fill and enable the machine do the sleep. This may ensure it is extremely easy to use, saving you commitment when compared with handbook methods being filling. Plus, the gear is adjustable to allow for product which is different, so that you can fill tiny or big containers with ease.

Among the numerous advantages of this oral stuffing that is liquid is its hygienic metal construction this is certainly stainless. Stainless steel is an perfect material for food and pharmaceutical production since it is easy to clean, resists corrosion and germs development, which is durable enough to withstand usage this is certainly hefty. This makes it a secure and choice this is certainly dependable filling liquid medications as well as other items which demand a level that is advanced of.

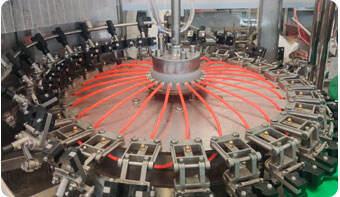

The GF Automatic Stainless Steel Oral Liquid Filling Machine could be constructed with advanced security features to keep users and products safe as well as its stainless steel construction. Included in these are a sealing system that stops spills that are fluid leakages, along side an shutdown this is certainly automatic in the event of breakdown or overload.

Other top features of this stuffing that is dental is liquid incorporate a tight size, that makes it an easy task to move and store; adjustable filling speed and amount control; and a user-friendly interface that means it is easy to run. This product is great for your requirements whether you'll want to fill big or small degrees of oral fluid products and services.

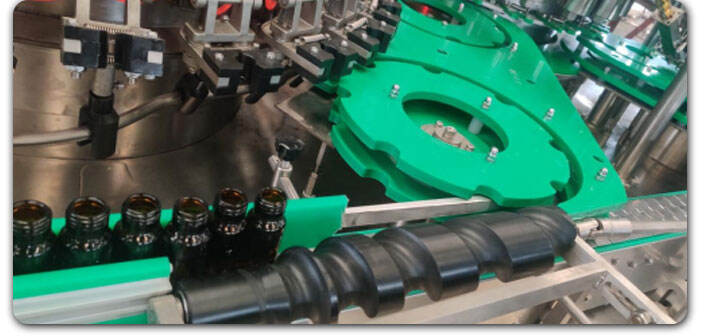

Bottle washing filling and capping 3 in 1 machine |

||||||

Model |

GFFDP18-12-4 |

GFFDP24-18-6 |

In addition to these models, we can customize according to your output requirements, so please contact us and tell us your needs

|

|||

Number of bottle washing heads |

18 |

24 |

||||

Number of filling nozzles |

12 |

18 |

||||

Number of capping heads |

4 |

6 |

||||

Production capacity(Depends on bottle capacity): |

3000-4000 BPH(50ml) |

5000-6000BPH(50ml) |

||||

Total power |

3 (kw) |

5.5(kw) |

||||

weight |

2500KG |

3500KG |

||||

Dimensions |

3800*1500*2200mm |

4200*1500*2200mm |

||||

Bottle height: |

50-320 (mm)customized |

|||||