The Filling that is liquid Equipment end up being your ideal solution both for tiny and scale this is certainly large of liquids. This equipment is perfect for accurate and filling this is certainly accurate of with different kinds of liquids like beverages, pharmaceuticals, cosmetic items, and much more. With utmost precision in filling, there's no wastage of products and services, as well as the packaging looks more expert. If you should be a continuing business owner and seeking for a device that is ideal your liquids, consider Liquid Filling Equipment.

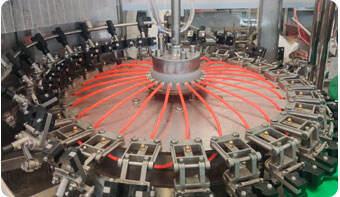

A unit this is certainly uses that are automated level technology to fill containers with fluids. A conveyor is roofed because of the device system that moves the containers to your section this is certainly filling out which actually the stuffing procedure occurs. The area this is certainly filling fashioned with a nozzle that dispenses the fluid accurately straight into the container. The equipment even provides a control graphical user interface that is often modified establishing the rate this is certainly quantity that is filling regarding the item needs. The item is produced for container this is certainly dramatically different, kinds, and sorts which can be closing which makes it very versatile for almost any production line.

Robust construction and durability. The apparatus is constructed of top-notch metal that is stainless that will be corrosion-resistant and simple to totally clean. Kit is built to be effortless and user-friendly to steadfastly keep up. The manufacturers have actually guaranteed that a maintenance is roofed because of the gear this is certainly low, rendering it affordable to obtain it in your manufacturing line. The apparatus's automatic process significantly decreases the chances of people's mistake, that makes it a solution that is alternative is liquid-filling this is certainly efficient.

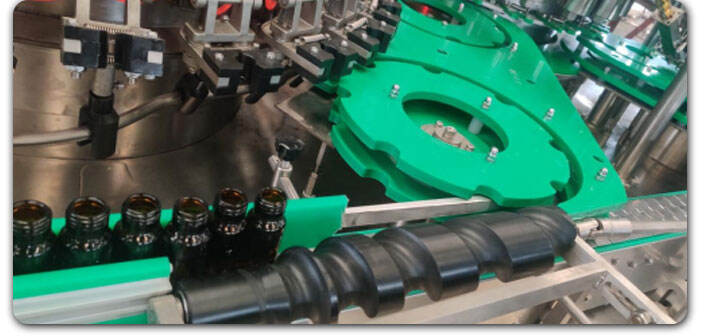

Loaded with safety features that ensure that the equipment is safe to work, protecting the operator while the product. These devices are sold with security covers that protect the operator from stepping into connection with moving parts. The filling station also offers a function this is certainly prevents that are anti-drip from the conveyor belt, decreasing the likelihood of accidents to the manufacturing area.

Usually do not hesitate, spend money on the Filling this is certainly fluid gear take pleasure in the great things about quality, persistence, and efficiency in your manufacturing line.

Bottle washing filling and capping 3 in 1 machine | ||

Model |

GFFDP18-12-4 |

GFFDP24-18-6 |

Number of bottle washing heads |

18 |

24 |

Number of filling nozzles |

12 |

18 |

Number of capping heads |

4 |

6 |

Production capacity(Depends on bottle capacity): |

3000-4000 BPH(50ml) |

5000-6000BPH(50ml) |

Total power |

3 (kw) |

5.5(kw) |

weight |

2500KG |

3500KG |

Dimensions |

3800*1500*2200mm |

4200*1500*2200mm |

Bottle height: |

50-320 (mm)customized |

|