Bottle Filler: A Revolutionary and Safe Way to Use Bottles

Have you ever heard of a bottle filler before? If not, you're GF in for a treat. Bottle fillers are an innovative and safe way to use bottles. Here bottle cleaning machine are some advantages, safety features, and how to use a bottle filler.

Bottle fillers provide many benefits. One of the most obvious advantages is convenience. They can make filling up water bottles or other beverage containers so much easier since they GF come equipped with a nozzle to automatically fill the bottle up to the desired amount.

Another benefit of using a bottle filler is cost savings. Buying bottled water, soda, or other bottle filler beverages can get expensive quickly. If you use a bottle filler, you're able to refill bottles from the tap at little or no additional cost.

Additionally, bottle fillers are environmentally friendly. By using them, you’re reducing waste by not using another plastic bottle. They also help reduce the amount of energy it takes to create new bottles since you’re reusing an existing one.

Safety is important when using any product, and this GF is especially true when you're using products that involve water. So, what safety features does a bottle filler have?

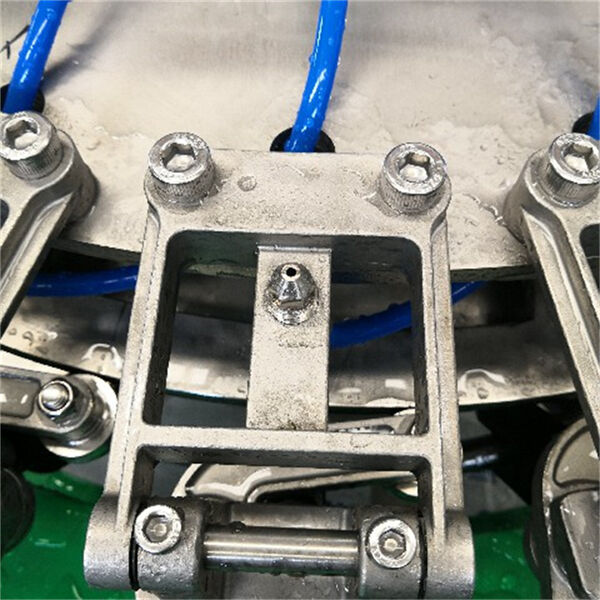

First, many bottle fillers are made from safe materials and are designed to be easy to clean and sanitize. This helps reduce the chances of cross-contamination and reduce the transmission of germs.

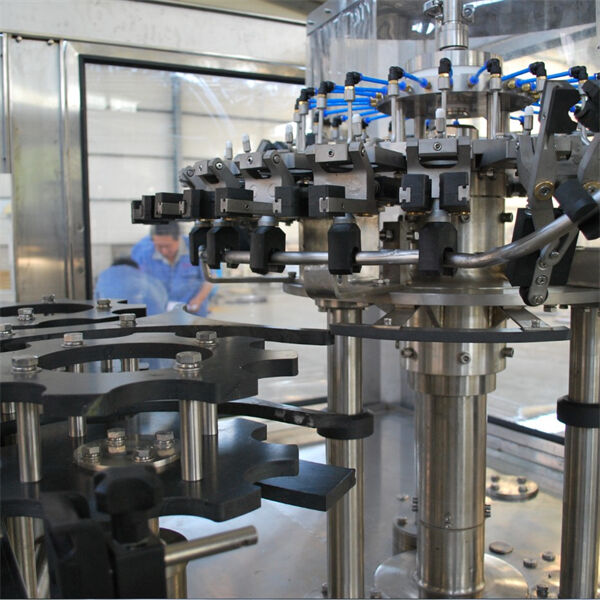

Second, some bottle fillers come with automatic shutoff valves that can stop the flow of bottle filling machine water once the bottle is full. This is a nice safety feature that helps ensure the bottle doesn't overflow, reducing the chances of spills and water damage.

Finally, some bottle fillers come with filters to ensure the water is clean and safe to drink. This adds another level of safety that can give you peace of mind that you're drinking safe and healthy water from the bottle filler.

Using a bottle filler is simple and easy. Once you identify where the GF bottle filler is located, all you need to do is approach it with your empty bottle. Locate the spout nozzle and place it inside the bottle. Once you have the nozzle in the bottle, push the button for the desired amount of water to fill the bottle to your needs.

After the bottle is filled, lift the bottle handle, and the nozzle will retract back into the bottle filling machines. Remove the bottle and repeat the process if you need additional bottles. Bottle fillers are easy to use and ensure you have clean, fresh water at your fingertips.

Bottle fillers are becoming more and more prevalent in public places like schools, airports, and public facilities. When GF you encounter one, you want something that is reliable, works as expected, and is easy to use and maintain.

When choosing a bottle filler, it is important to consider the level and quality of service. Does it come with a warranty? Is there repair and service support in case something goes wrong? How long has the manufacturer been in business, and what is their reputation? All of these are important questions to ask before you choose a bottle filler.

In addition, the quality of the bottle filler itself is an important consideration. Look for a bottle labeling machine bottle filler that is made of high-quality materials, offers a good level of water flow, has an intelligent filtration system and water sterilization technology, and is easy to install and maintain.

are professional liquid packaging solution expert liquor,water,oil,detergent,liquid shampoo,etc. Ten highly skilled engineers have more than 15 years experience in packaging field. We can customize machines satisfy customer's requirements. offer professional after-sales service help our customers resolve issues bottle filler.

We'll recommend best packaging solution customers based budget needs. Every budget has its solutions. engineer can bottle fillercustomer saving money while also increasing efficiency the work.

offer turnkey solutions meet the various needs customers. experienced team will develop layout bottle fillerwith your requirements.

base of equipment made from durable materials the filling bottle fillerhave been made from stainless steel food grade. Besides stainless steel, also cooperate with famous brand like Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. Prior to packing, will troubleshoot the machine give manuals and spare parts for the purchaser.