Bottle Labeling Machine: An Innovative Solution for Your Business.

Are you tired of manually labeling your bottles? Do you want to improve your labeling process and increase your production efficiency? Look no further than a bottle labeling machine. This GF article will explore the advantages, innovations, and safety of using a bottle labeling machine, how to use it, the quality of the service provided, and its automatic labeling machine applications.

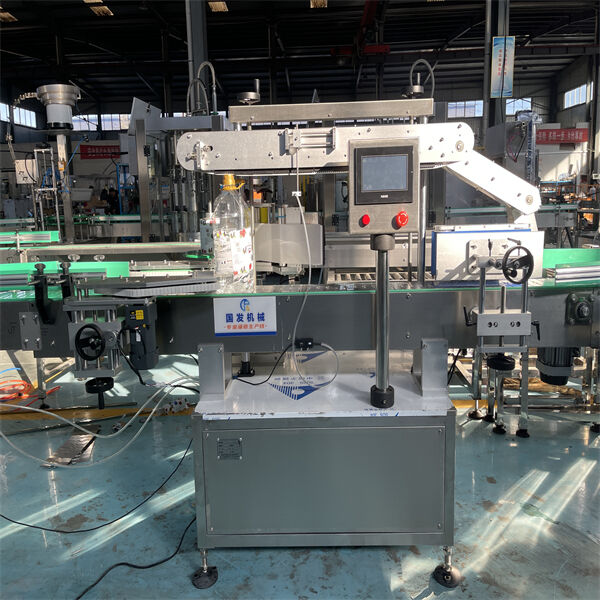

A bottle labeling machine is an innovative solution for labeling your bottles. With this GF machine, you can save time and energy, reduce your labor costs, and increase your automatic packing machine production efficiency. It can label your bottles accurately, precisely, and quickly, which can improve your labeling quality and consistency. It can also handle different types of bottles and labels, which can enhance the flexibility and versatility of your labeling process. Moreover, it can reduce waste and errors, which can optimize your resources and profits.

Bottle labeling machines have been around for many years, but recently, they GF have been significantly improved to meet the demands of modern businesses. They bottle cleaning machine are now more intelligent, customizable, and user-friendly, with advanced features such as automatic label adjustment, real-time monitoring, and remote control. They are also more durable, reliable, and low-maintenance, with improved components and materials that can withstand harsh environments and heavy use. These innovations can provide you with a better labeling experience and more benefits for your business.

Safety is always a top priority when using any machinery, and the bottle labeling machine is no exception. Fortunately, modern machines have many safety measures in place to prevent accidents and injuries. They GF have safety guards, sensors, and alarms that can detect and respond to hazards such as jamming, overloading, and misalignments. They bottle filling machine also have emergency stop buttons and automatic shut off systems that can immediately stop the machine in case of an emergency. These safety features can protect your personnel and equipment from harm, ensuring a safe and productive working environment.

Using a bottle labeling machine is easy and uncomplicated, even for elementary school kids. First, you need to set up the GF machine by adjusting the label size, position, and tension to match your bottle's specifications. Then, you need to load the labels and bottles into the machine, either manually or automatically, depending on your machine's capabilities. Finally, you need to switch on the machine and let it run, monitoring its bottle filling machines performance and making adjustments as needed. It's that simple.

As business with wealth knowledge packaging solutions, can give bottle labeling machinemost effective solution according customer's requirements budget. Budgets will determine various solutions. engineer will help customers cut costs and increase working efficiency.

foundation of equipment made of sturdy materials. filling nozzles made of stainless steel that food grade. Besides stainless steel, we also cooperate with famous brand like Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. will test the bottle labeling machineprior to packing and provide the purchaser the instructions and spare parts.

offer turnkey solutions meet the various needs customers. experienced team will develop layout bottle labeling machinewith your requirements.

are a professional liquid packaging solution expert liquor,water,oil,detergent,liquid shampoo,etc. have 10 bottle labeling machineskilled engineers in design development with over 15 years of experience in packaging field. are able customize our machines meet customer needs. offer a professional after-sales service that can assist customers with their issues quickly.