- Что-то не так?

Пожалуйста, свяжитесь с нами, чтобы мы могли вам помочь!

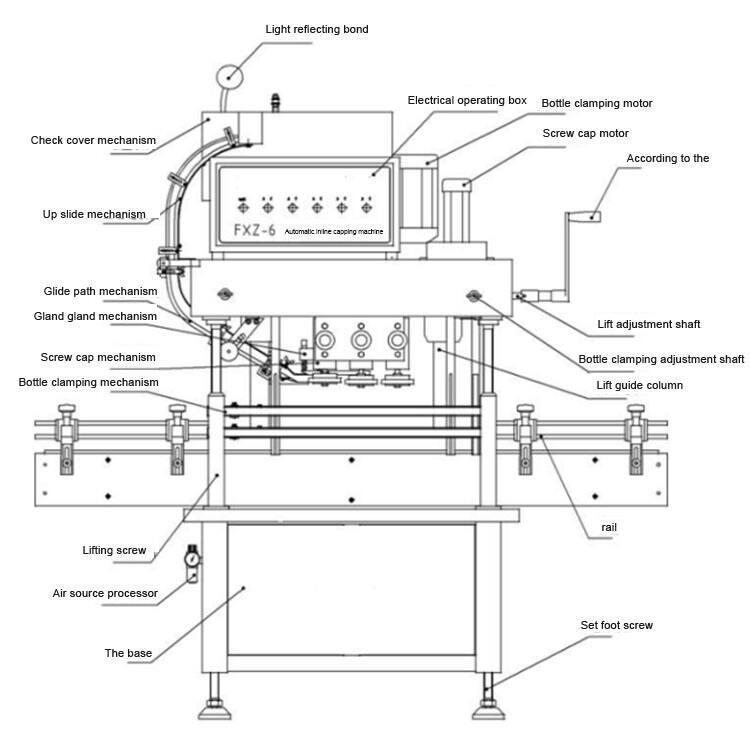

Автоматическая линейная машина для укупорки бутылок с распылителями GF Linear Six Wheel Sealing Bottle Sprayer действительно является революционным продуктом в упаковочной индустрии, который безусловно предназначен для точного и легкого закупоривания бутылок с распылителями. Этот продукт работает на шести колесах, которые взаимодействуют, чтобы обеспечить герметизацию, которая безупречна во времени.

Автоматическая линейная машина для укупорки бутылок с распылителями GF Linear Six Wheel Sealing Bottle Sprayer создана из самых высококачественных материалов, чтобы гарантировать ее большую надежность и долговечность. Корпус изготовлен из металла, что делает его устойчивым к коррозии и износу. Он также изготовлен с использованием точной инженерии, чтобы гарантировать плавную и эффективную работу.

Товар будет работать для организаций, которые производят множество продуктов, таких как, например, бытовая химия, системы личного ухода и товары для ухода за домашними животными. Этот продукт может использоваться для укупорки бутылок различных форм и размеров, что делает его универсальным и идеальным для разных компаний.

Одним из многих выдающихся выборов, связанных с автоматической линейной шестиколесной системой укупорки бутылок с распылителем GF, является её эффективность. Она может запечатывать до 300 бутылок в минуту, что значительно снижает время производства и оптимизирует производственную линию. Это означает, что компании могут производить больше продукции за меньшее время, увеличивая прибыльность бизнеса.

Устройство GF автоматизированного линейного шестиколесного уплотнения бутылок с распылителем и закручивателем может быть воплощено в красивом исполнении с учетом безопасности ваших мыслей. Оно действительно разработано с защитными ограждениями и датчиками, которые обеспечивают немедленную остановку аппарата при обнаружении аномалии. Это защищает операторов от несчастных случаев и помогает обеспечить безопасную работу системы.

Этот продукт прост в использовании и обслуживании. Он построен на базе компьютерной программы, которая интуитивно понятна для создания и изменения параметров легко. Поддержание его всегда является простой, чистой задачей, что снижает простои и повышает эффективность производственной линии.

Модель |

GFCG-6 |

||||||

Производственная мощность |

Макс. 8000 бутылок в час |

||||||

Количество закрывающих головок |

6 |

||||||

Подходящие диаметры крышек |

φ20~60мм |

||||||

Подходящие диаметры бутылок |

φ25~120мм |

||||||

Напряжение |

220В,50Гц/60Гц, однофазное или настраиваемое |

||||||

Мощность |

2КВт |

||||||

Общие размеры (Д*Ш*В) |

2000×950×2100мм |

||||||

Вес |

480кг |

||||||

Источник воздуха |

0.4~0.6Mpa |

||||||