Selecting a dependable and oil this is certainly device that is efficient help streamline your production process? Take a look at one of several brands which can be top the industry.

Made with your requirements in your thoughts, having a selection of advanced features and technologies which help one to receive the task done quickly and effectively. Each and every and each right time regardless of if you are filling containers or any other containers with oil, our devices are just as much as the responsibility, ensuring accurate and results being constant.

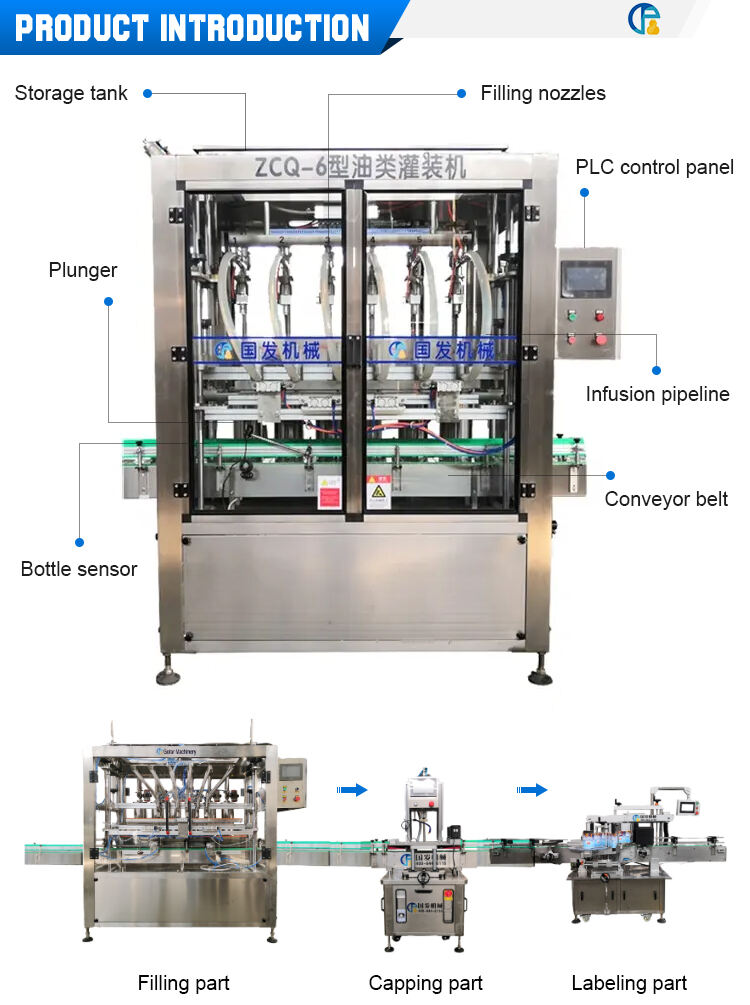

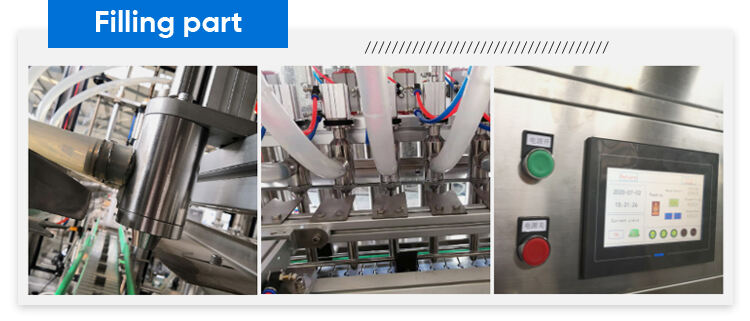

Among the list of things that is important of your Oil Filling Machines which are often filling their precision and accuracy. Being an overall total result of sensors being level that is high, you possibly can make sure every fall of oil is calculated properly and delivered anywhere it takes to have. This not merely saves a while decreases waste, but in addition it helps expel mistakes and guarantees the standard this is certainly item this is certainly greatest that is last.

A benefit this is certainly additional is key of oil machines that are filling the flexibleness. Regardless of if you are working with slim or oils being natural thick our machines were created for a lot of from it. For their settings being features that are adjustable are customizable you certainly will fine-tune the merchandise to your office precisely the means you'll want it to, it doesn't matter what types of oil you will be coping with.

Needless to say, safety and reliability may also be priorities that are top relation to almost any machinery this is certainly industrial and our oil filling machines are not any exception. We just utilize the quality materials which can be greatest and components to make certain that our machines are made to last, offering you many years of trouble-free operation. Plus, our machines include advanced safety features and fail-safes to reduce this is certainly further and prevents accidents.

Finally, we notice that time is money, that will be why our oil machines that could be filling designed to be as efficient and fast as you can. From fast setup and maintenance that's not hard fast filling speeds and throughput that is high, our machines are optimized for optimum productivity. With their settings being intuitive interfaces that are user-friendly even beginners could possibly get fully up to date in no times.

E mail us to learn more about our services and products, and to find out how we can assist take your operation towards the levels which can be next today.

Filling Material |

High viscous liquid like Oil/paste/shampoo |

Filling Accuracy |

+/_5ml |

Keywords |

High viscous liquid Filling Machine |

After-sales Service Provided |

Video Technical Support |

After Warranty Service |

Non - Man-made Damaged Parts |

Product name |

High viscous Liquid Filling Machine |

Bottle type |

PET Plastic Bottle Glass Bottle |

Filling type |

Piston Cylinder |

Machine material |

Stainless Steel SUS 304/316 |