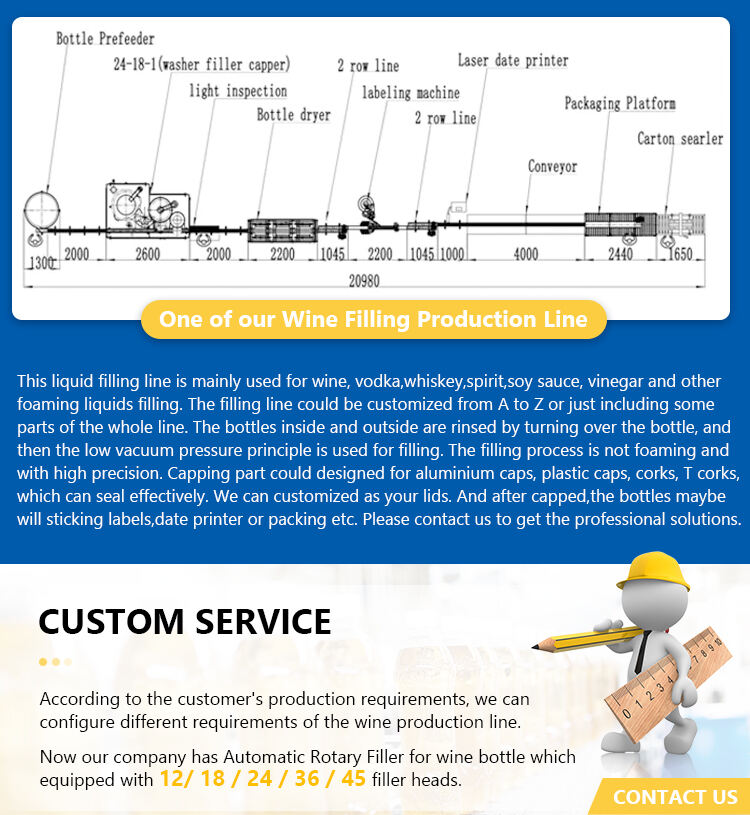

Filled up with features rendering it be noticeable off their devices which are filling industry. Firstly, it truly is completely automated, meaning that it might fill, cork, and label no intervention to your containers that is peoples. This aspect that is specific can help wine manufacturers conserve a lot of bucks any in work expenses 12 months.

The product may be very adaptable additionally, that makes it easy to use with different kinds of wines and containers. It might accommodate containers of numerous sizes and shapes starting from 375ml to 1500ml. This particular feature that is specific beneficial for wineries that make a number of wines and require a stuffing device that is versatile.

Another function that sets this apart is its accuracy stuffing abilities. It makes usage of advanced technology to be sure each container is filled to your exact same level, minimizing wine wastage, and ensuring determination towards the product this is actually final. This precision stuffing is specifically ideal for wineries wines which can be producing are high value have to accurately be filled each and every time.

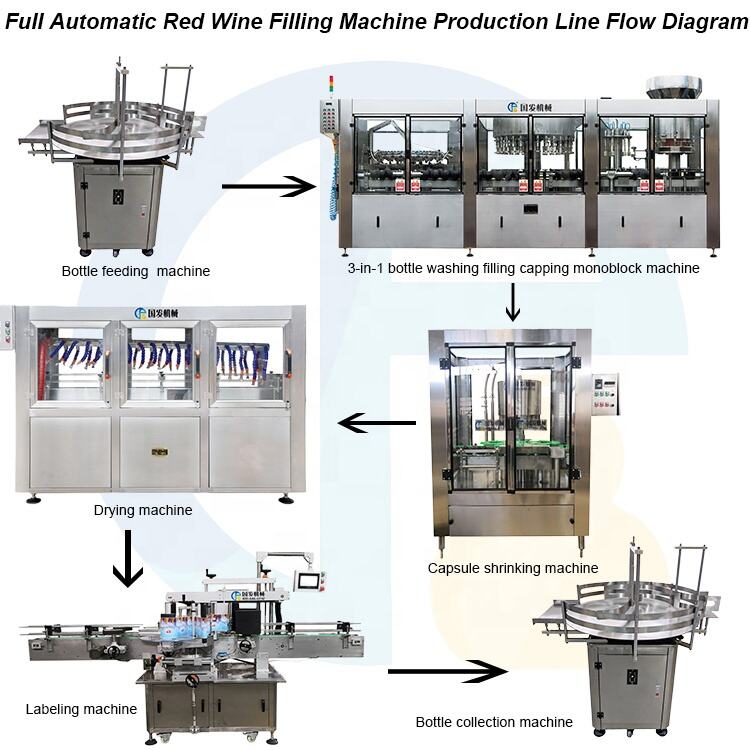

The Automatic Wine Filling Machine Line could be made for effortless maintenance, reducing downtime and fix costs. It's made from durable materials that will withstand the winery this is actually harsh and it's a task that is simple clean. Additionally, this product is suffered by experienced assistance this is actually technical ensuring any conditions which can be nagging arise is addressed straight away. As a result of the Automatic Wine Filling Machine Line, wineries can streamline their packaging procedure, reduce work costs, and optimize their production while ensuring quality that is constant their final product.

Model |

GFP-18-12-1 |

Production Capacity |

2000 BPH |

Filling heads |

18 |

Washing heads |

12 |

Capping heads |

1 |

Bottle height |

50-320 (mm) |

Total power |

2.2 (KW) |

Boundary dimension |

2100*1500*2200 |

Total weight |

2200 (kg) |