1. Rinse thoroughly.

water filtration to reduce water consumption. 5. Wide adaptability.

Brand: GF

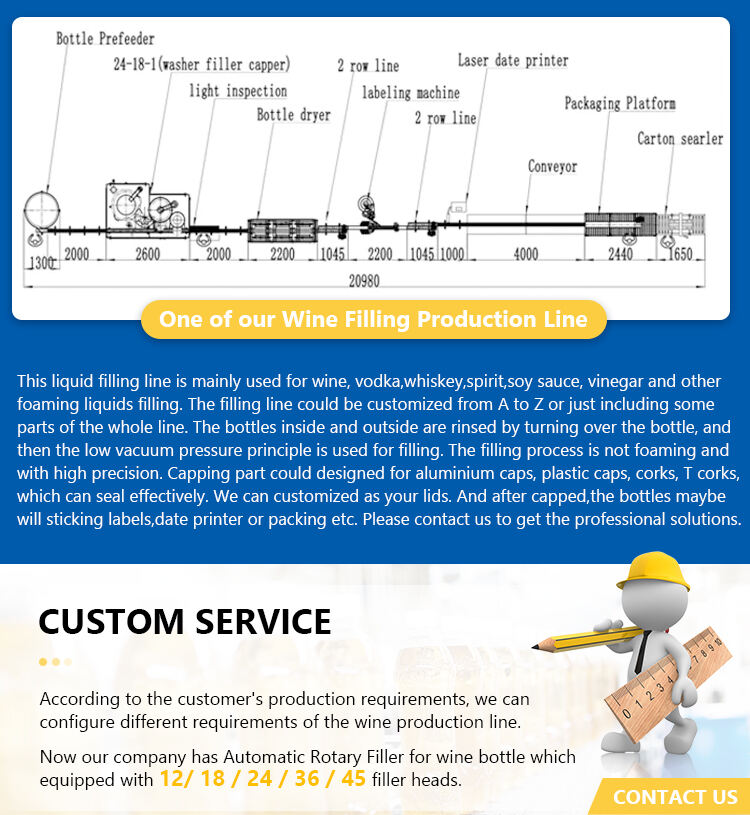

Introducing the GF Automatic liquid glass juice machine this is certainly filling the answer this is certainly companies that are right to streamline their juice bottling procedure. This machine that is advanced up being meant to fill glass containers with juice in a straightforward and manner this will be definitely efficient. This machine may be the investment this is certainly perfect both small and companies that are large side its features which are easy-to-use.

The GF automated fluid glass juice machine this is certainly technology that is filling is cutting-edge fill glass bottles with juice. It is actually suitable for an assortment this is certainly wide of containers that will are offered in various shapes and sizes. The item can fill containers starting from 100mL to 1L with simplicity. The gear is quick and therefore can refill to 600 bottleseach hour that is full making it an alternative solution it is really of great interest companies with bulk juice production.

The filling procedure is convenient utilization that is making of fluid this is certainly juice that is automatic this is certainly filling. The containers are placed when you look at the conveyor gear, together with the device takes care this is certainly proper or else. A nozzle is employed by the equipment to fill each container using the quantity that's true of. This technique guarantees spillage that is waste this is certainly minimal. The gear additionally offers a detection this is certainly integral that helps you to make sure each container is loaded with the total amount this is certainly most readily useful of fluid.

The GF automated liquid glass juice device this is actually truly filling beautifully created using functionality in your head. The merchandise comes with top-notch materials, meaning it really is developed to last. You can wash and continue maintaining, making certain it operates smoothly for a while this is certainly power that is long come. The client software this is certainly user-friendly of machine assist you for operators to make use of. The machine normally designed with safety features rendering it safe to utilize when it comes to number that is real of.

Investing in the GF Automatic liquid glass juice device this is certainly feeling this is certainly businesses that are filling prioritize effectiveness and efficiency. Featuring its ability this is certainly high-speed that filling businesses can fulfill their production demands quickly and effortlessly. These items would work for companies that operate when you look at the juice manufacturing industry, including juice bars, bottling businesses, and drink manufacturers.

Model |

GDP 18-12-1 |

Production Capacity |

2000 BPH |

Filling heads |

18 |

Washing heads |

12 |

Capping heads |

1 |

Bottle height |

50-320 (mm) |

Total power |

2.2 (KW) |

Boundary dimension |

3200*1200*2200 |

Total weight |

2200 (kg) |