Launching the GF Viscous fluid Filling Machine, your solution that is new that go-to fast and efficient fluid filling processes. Made with user convenience and precision in your mind, our filling this is certainly device that is automatic for businesses trying to streamline their manufacturing lines.

The GF Viscous Liquid Filling Machine was designed to handle a number of thick things that are liquid ease. Its mechanism is tailored to carry out fluids that are viscous in terms of instance syrups, gels, ointments, as well as pastes at a rate that is impressive. This filling machine can deliver your liquid filling needs with perfect precision whether you are in the meals, cosmetic makeup products, or pharmaceutical companies.

At GF, we understand that time is associated with essence during manufacturing runs, and our device that is filling assists achieve exactly that. It boils down designed with state-of-the-art motor this is certainly automatic which means every drop of fluid accurately fills the container. Along with its precise and fast filling capabilities, you will see a enhance that is dramatic production and productivity.

Our filling device boasts an ergonomic and design that is user-friendly simplicity that is ensure. Its laden with an operator touch screen user interface that allows for a stuffing process that is customizable. This implies you can easily modify the functions predicated on the needs you have, such as for instance fill rate, product volume, bottle size, and a lot more.

The GF Viscous Liquid Filling Machine's lightweight and construction that is longevity that is robust. Made of top-notch materials, it could withstand long and production this is certainly heavy-duty. These devices' setup and cleaning procedures may also be remarkably easy and simple, guaranteeing upkeep that is low.

Aided by the GF Viscous Liquid Filling device, you'll sit back and relax even though device does every one of the works. Its automatic stuffing system guarantees wastage that is minimized reduced work costs, and increased effectiveness, leaving your employees doing whatever they do best- quality control.

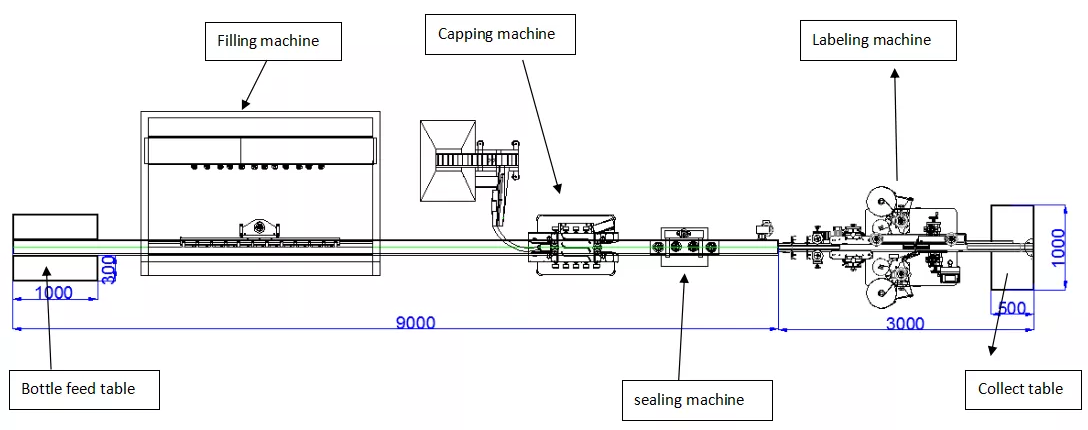

The oil filling production line introduction

The automatic thick paste oil bottling filling production line is stable and reliable, with high degree of automation, continuous longer than similar products, simple maintenance of the whole line, strong coordination and consistency of all equipment of the whole line, design is reasonable and so on,.The filling machine with servo motor,PLC program ,touch screen to control,easy to operate and control.Oilliquidfilling bottling line the whole packaging process is environmentally friendly, higher and safer. The production line has been well received by customers at home and abroad.

Gofar Packaging Machine, the expert in liquid bottling filling line, will always provide you with the best solution for your products.In Texas,Vienna,Lima,Tanzania etc,we have bottling line case.

Bottling Line |

Oil Bottling Production Line |

|

|

|

|

Filling nozzles |

|

|

|

|

|

Peoduction capacity |

|

|

|

|

|

Applicable bottle height |

160~360mm,could customized

|

|

|

|

|

Applicable bottle diameter |

Φ50-Φ100,could customized

|

|

|

|

|

Filling Volume |

100~5000ml or customized |

|

|

|

|

Filling accuracy |

±0.01% |

|

|

|

|

Overall size (L*W*H)(mm) |

3000*1500*2200 |

|

|

|

|

Automatic Servo Oil Filling Machine

1. The automatic filling machine speed could with500bph ~2000bph.

2.The filling volume could be adjusted via touch screen,easy to operate and control.3. The material of filler contact with sauce or exposed to the air is SUS 304, which under the level of National Food Hygiene Standard.

4. The filling precision of the filler is very accurate.

5. The compatibility range of the filler is very high,even though for glass bottles,plastic bottles,PET bottles.

6. The action of filling is carried out under closed condition, which ensures the sanitary requirement.

1.The filling nozzles could do 4/6/8/10/12 to meet different production capacity need.

2. The filling nozzle with anti-dripping design which ensure the machine and production cleanliness.

3.The filling nozzles with food grade SUS304 matierals to make sure more hygiene.

4.No bottles no filling,saving liquid.

5.The filled liquid in the bottles are at the same level and filling volume could be adjusted.

Bottle height Adjusting

If you have different height bottles,you could adjusting the filling nozzles height via this hadnwheels.It is easy to operate.

Touch Screen

1. The machine could with this kind touch screen.Easy to operate and control.As the language,we could do as your local language.

2.The speed could adjusted to matching with your production line.

Automatic Capping Machine

1. The machine has an wide using range.It could used various size caps sealing.such as for normal screw caps,

spray pump caps,flip caps,conical caps etc.

2. The machine with PLC program and touch screen,easy to operate and control.

3.The capping wheels with PU materials,

no slip,no scratch.

4. Caps screwing strength and force,and capping speed could adjustable.

5. Bottle clamping strength and screwingheight are adjustable to matching different size bottles.

Automatic Labeling Machine

1. PLC control with large-scale human-machine interface, easy to read, easy to read, beautiful. Multiple sets of labeling parameters memory for fast replacement of products.

2. The whole machine is stainless steel and anodized aluminum is made of high-level, never rust, meet the GMP standard.

3.The machine features a bottle guide is, sub-bottle, label lost level, counting among others. Labeling position, height,

adjustable.

Q1.How long will take for the delivery of product?10 days for standard model, if machine in stock, will delivery immediately, customized model depend on customer requirements,usually about 20~30 days.

Q2.What's the insurance of after-sale service after purchase?

All our products, will be totally tested by QC department before delivery, with strict quality control process. The product is cost-effective during use, stable and reliable. One year warranty service for all machine, please feel free to contact us if you have any questions.

Q3.When the machine arrives at the work site, is it easy to install?

How to solve the problem of quick installation and use?

All machine model with installation video, to show the installation process more intuitively, and we will provide remote video technical support to solve your doubts and ensure that your installation is correct.

Q4:During the use of the machine, how to get after-sale service?

We have professional foreign installation and commissioning engineers, which have many years of experience in foreign debugging with deeply recognized by customers. We will provide on-site installation and commissioning services for foreign customers, and we will guide your workers directly.

Q5:Will the accessories change frequently with machine?

The service life of the accessories is related to the daily maintenance. When ordering, we will give you free wearing parts and provide you with daily maintenance strategies.