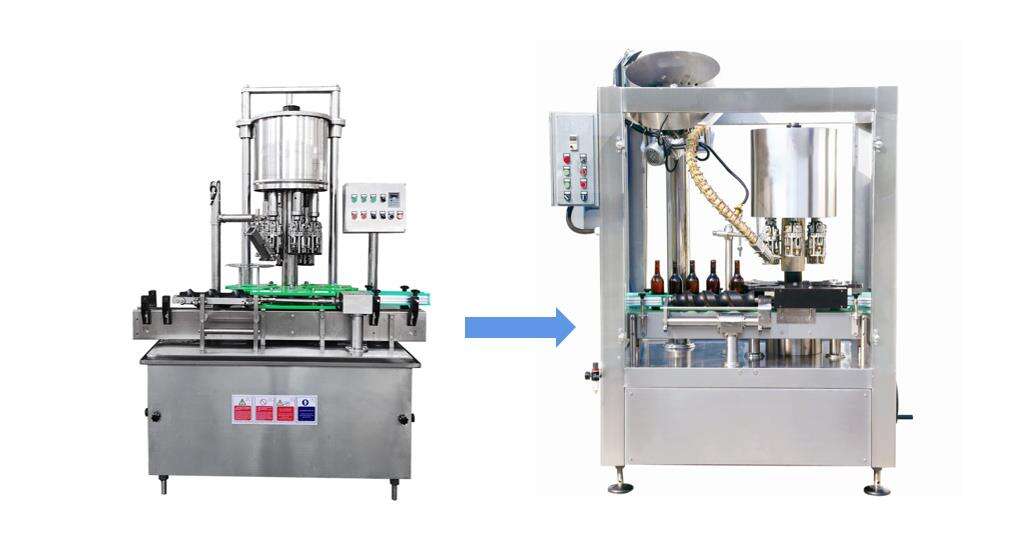

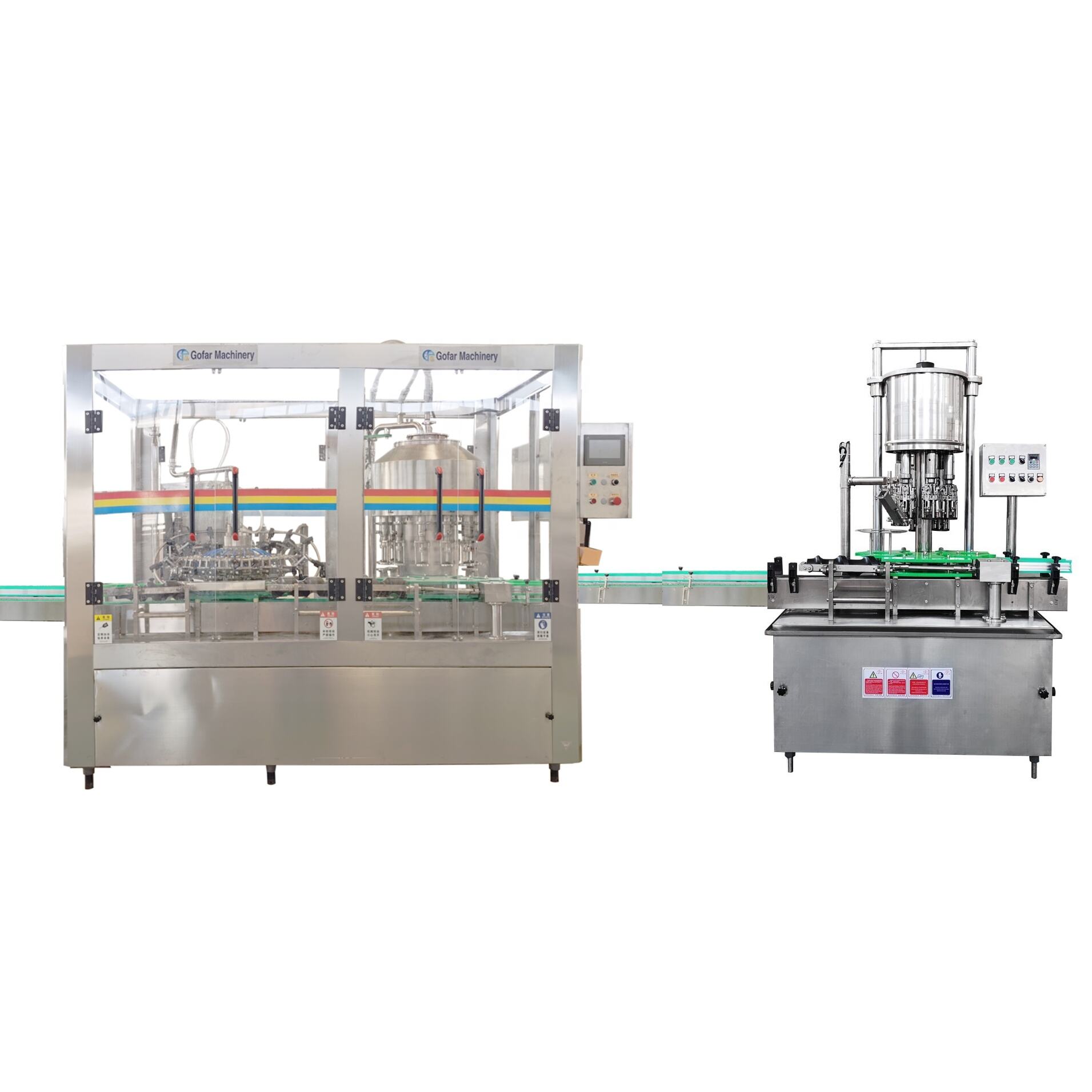

The GF Automatic Aluminum Glass Bottle Cover Capping Machine is the solution that is perfect those who struggle with manually capping containers. This machine was designed to quickly seal caps onto aluminum cup containers.

Produced from top-quality materials, this capping machine was designed to be durable and long-lasting. It comes down with a design that is rendering that is compact an easy task to store and transport.

This device this is certainly capping by automatically containers that are capping aluminum lids. It is built to work with a variety of different sized bottles, rendering it an instrument that is versatile any business.

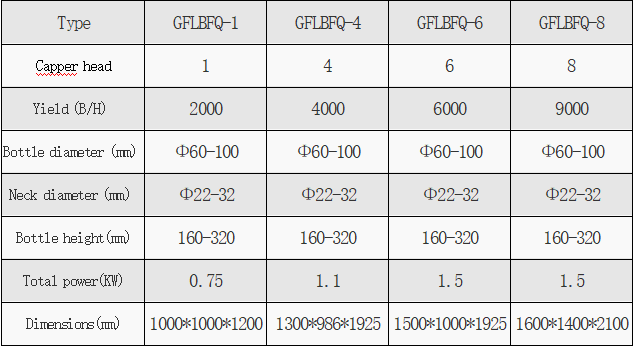

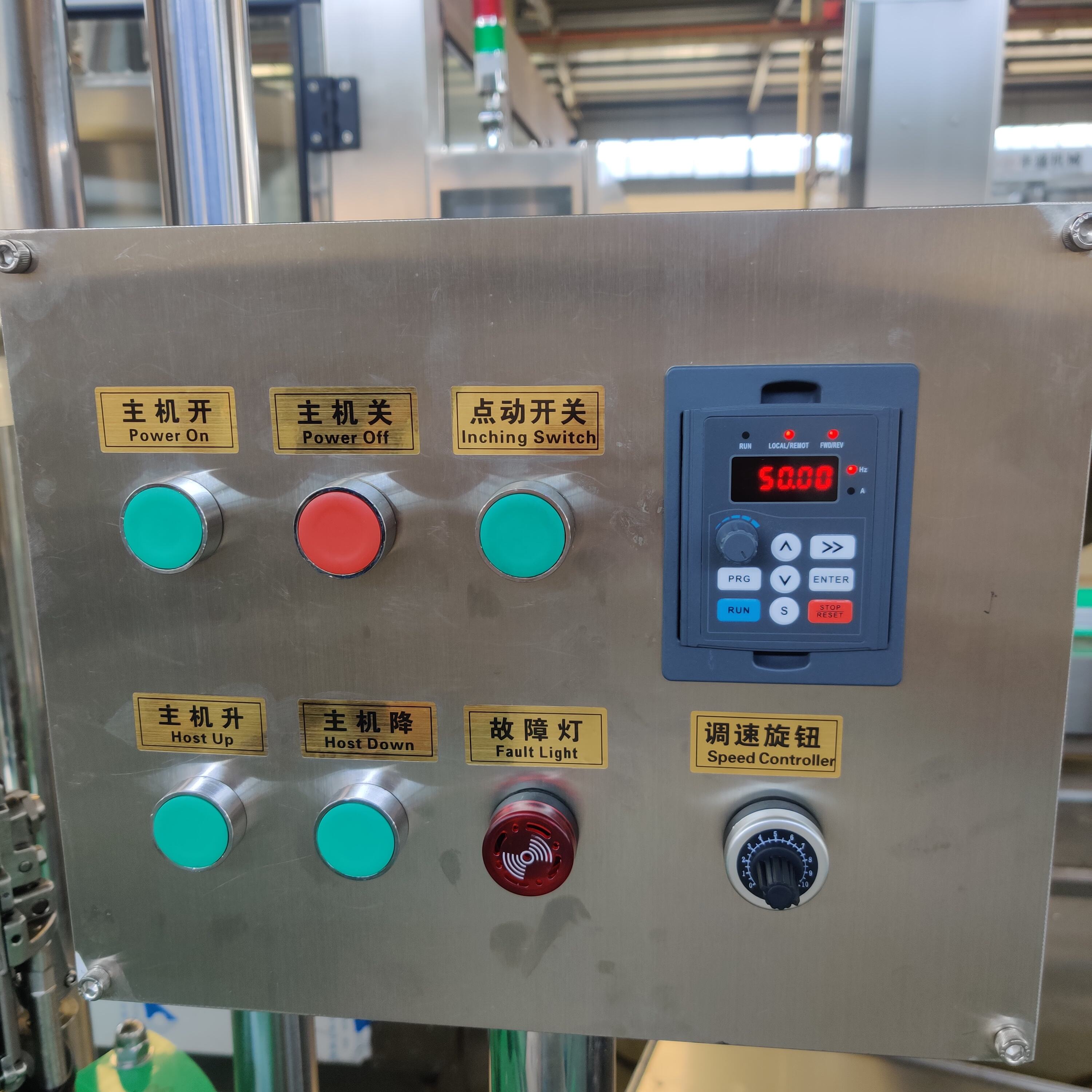

The GF automated Aluminum Glass Bottle Cover Capping Machine features an control that is easy-to-use, allowing you to regulate the speed that is capping torque to suit your certain requirements. The device additionally features an stop that is automated that stops over-tightening of caps, ensuring consistent sealing and preserving the grade of your product.

The capping head associated with the machine is manufactured away from high-quality materials and is built to be gentle in your bottles, making sure they may be not damaged through the procedure that is capping. Its accuracy capping technology ensures that the caps are evenly sealed onto the bottles, offering your item a finish that is professional.

This capping machine is built to be simple to clean, with a capping this is certainly removable and surfaces that are easy-to-clean. It needs maintenance this is certainly minimal can easily be disassembled for cleaning and maintenance.

The GF automated Aluminum Glass Bottle Cover Capping device is ideal for used in a quantity of companies, including drink and food, cosmetic cosmetic makeup products, and pharmaceuticals. Its design that is compact and features give it time to be the addition this is certainly perfect any production line.