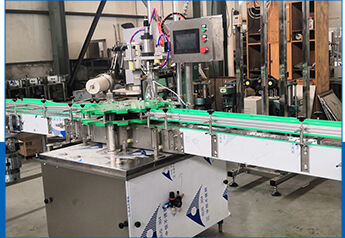

Searching for an easy-to-use and device that is efficient is bottling can manage your entire requirements? Look absolutely no further than the automated Single Head Bottle Corking Capping Filling Machine from GF This product that is perfect that is top-of-the-line small and medium-sized businesses seeking to get their products or services bottled quickly and effortlessly.

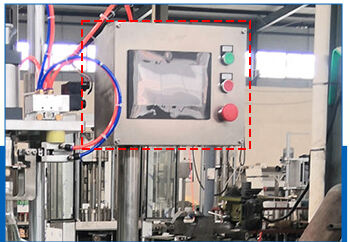

One of the standout features of the GF Automatic Single Head Bottle Corking Capping Filling device is its versatility. All of it with ease whether you need to cork wine bottles, limit bottles of non-alcoholic drink, or fill bottles along with your signature dressing or sauce, this revolutionary product are designed for. Plus, using its easy-to-use controls and operation that is automated you can easily enjoy bottling that is hassle-free time.

Another feature that is great of GF automated Single Head Bottle Corking Capping Filling device is its efficiency and rate. Each and every minute, making it ideal for small-batch bottling or production that is medium-sized with its effective motor and easy-to-adjust settings, you can bottle up to 30 containers. Plus, along with its design this is certainly easy-to-clean and that is sturdy maybe you are certain that your device will last for years in the future.

Of course, one of the most essential areas of any bottling machine is its precision. Which is where in actuality the GF Automatic Single Head Bottle Corking Capping Filling Machine really shines. Having its precise filling and capping mechanisms, you are confident that every bottle will more than likely to be filled towards the degree this is certainly exact need, and that every cap or cork will soon be perfectly sealed. This implies less wasted product, and better-quality bottles for your clients.

Finally, it's worth mentioning the client this is certainly exemplary which help that GF provides with every and each device. The friendly and staff that is knowledgeable GF are often there to help whether you'll need help setting up your device, troubleshooting a concern, or maybe have a concern regarding the bottling process.

Model |

DS-1 |

DS-4 |

DS-6 |

Press Head |

1 |

4 |

6 |

Max capacity(Bottle/H) |

2500 |

4500 |

6000 |

Power(kw) |

1.5 |

3 |

3 |