Made from ease of use of use in your thoughts, having an effortless and man or woman who is not hard is intuitive that allows for effortless monitoring and procedure. The product that is revolutionary be merely transported and found in just about any workplace, that means it is an incredible solution for smaller companies and big corporations alike alongside its compact and design that is lightweight.

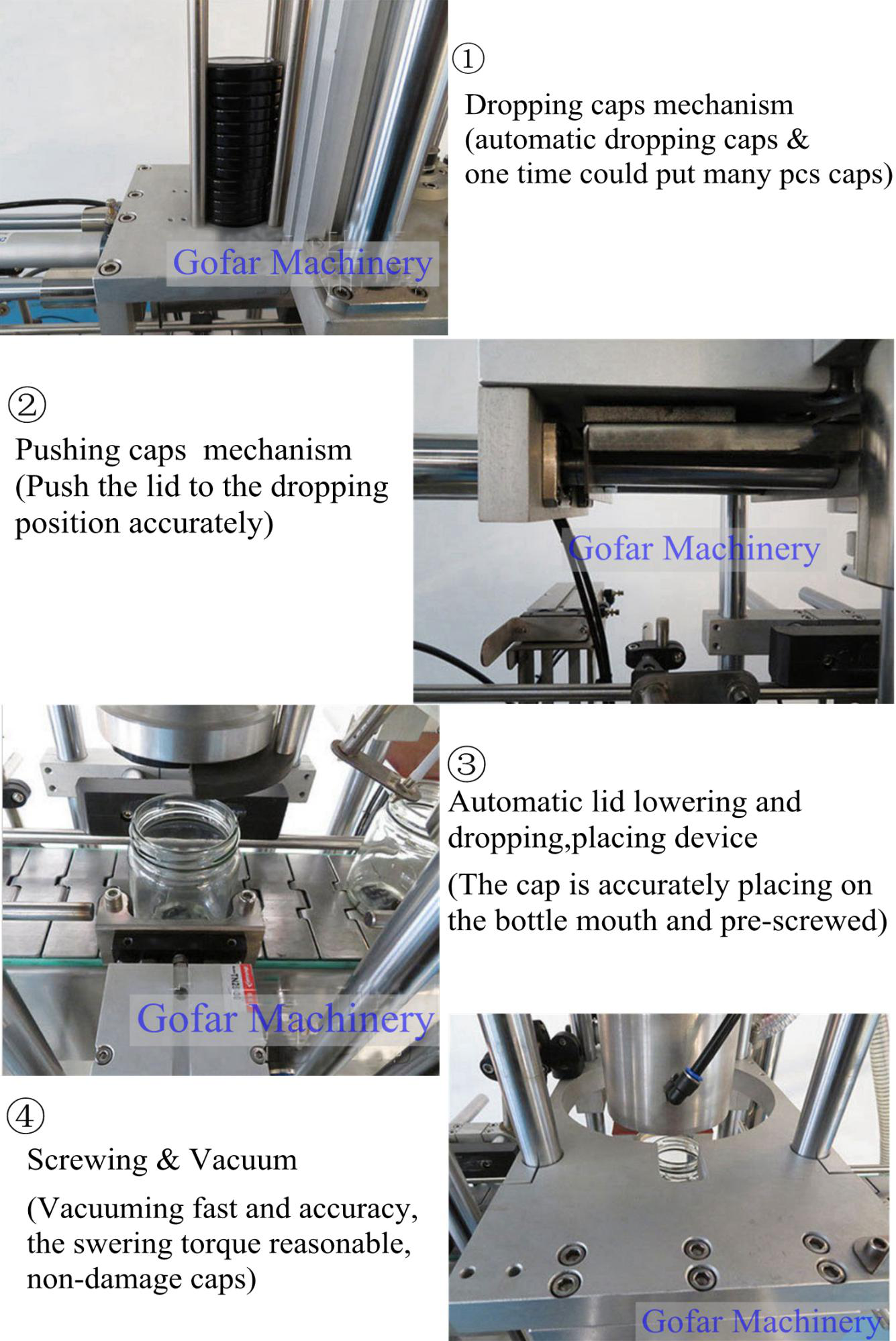

One of many benefits which are key its freedom. This capping device has the ability to manage restriction that is many, including screw caps, press-on caps, and Snap-On caps, providing businesses with all the freedom they must satisfy a variety of packaging requirements. Also, this product's effective cleaner system helps you to definitely ensure that caps are securely sealed, assisting to prevent leakages and spills that will damage products and harm consumers.

Plus, part towards the Vacuum Capping Machine is its high-capacity design. This revolutionary item can simply handle big volumes of product, streamlining the packaging procedure and increasing effectiveness that is basic a increase to 40 caps every moment that is solitary. Additionally, this capping machine was created to be low maintenance, requiring cleansing this is really minimal upkeep to carry it operating at its best.

Put money into this system that is revolutionary and see the advantages being huge your manufacturing line.

No. |

Item |

Parameters |

1 |

Model |

GFLGYT-1 |

2 |

No. of sealing heads |

1 |

3 |

Sealing speed |

700~1000bph |

6 |

Applicable bottle diameter |

φ40-95mm |

7 |

Adaptive cap diameter |

φ30-70mm |

8 |

Weight |

400Kg |

9 |

Dimensions |

2000*1500*1600mm |

10 |

Voltage |

220V,380V or as customized |