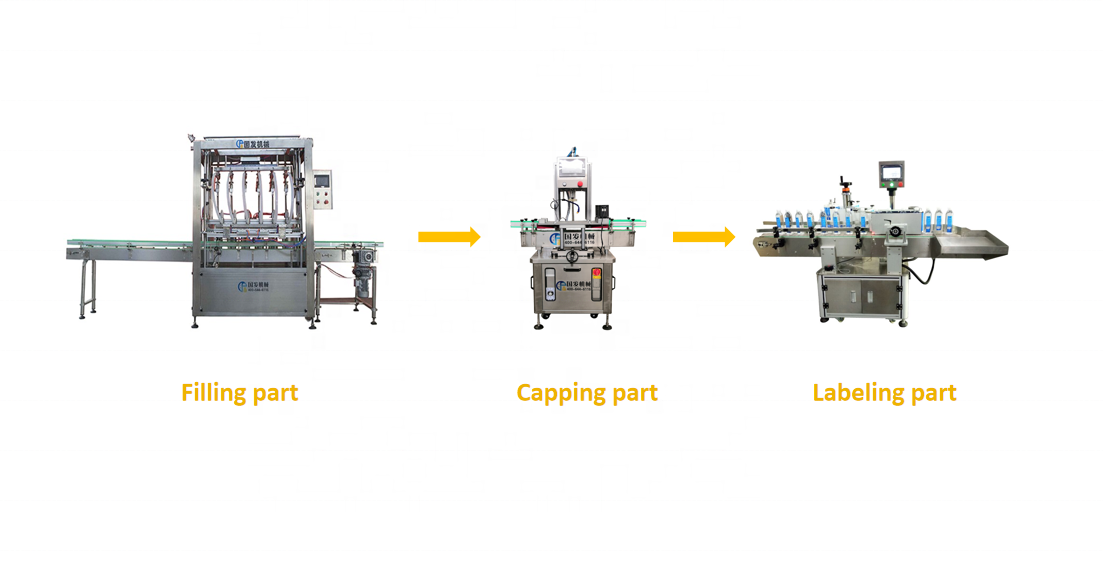

GF automated High Efficiency Viscous Oil Liquid Filling device is actually a dependable and solution that is efficient filling viscous oils and fluids in many containers. This machine comes with advanced level features that ensure precision, persistence, and productivity in virtually every stuffing operation.

All of it with ease whether you will want to fill jars, bottles, cans, or other forms of containers, this device was created for. Its high-speed ability this is certainly filling one to refill to 4000 bottles per hour, therefore you will get more done in less time.

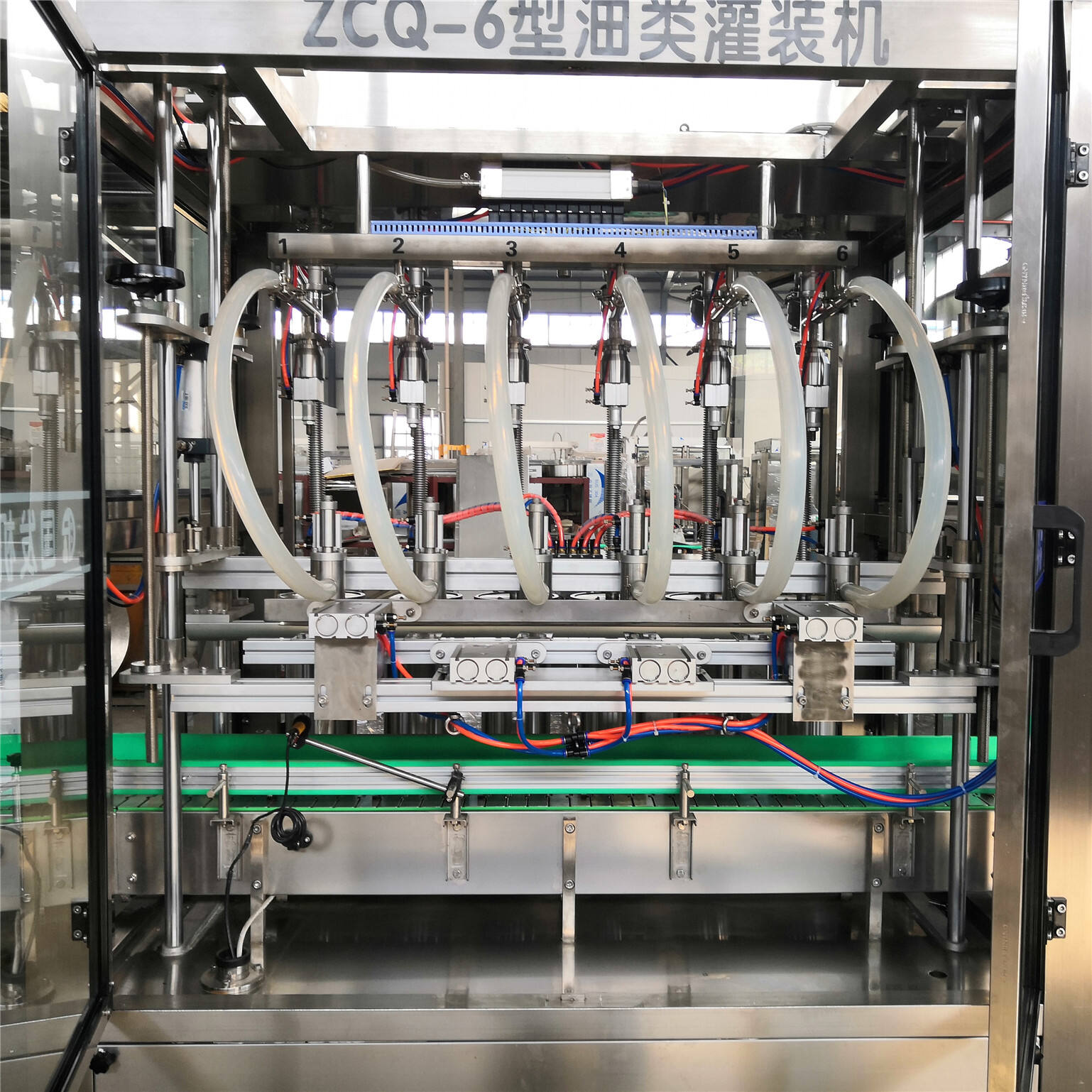

One of the key top features of this product is its filling that is system that is automatic the necessity for manual labor. This implies you can save some time labor expenses while keeping criteria being top-notch.

The GF automated High Efficiency Viscous Oil Liquid Filling Machine is made to make use of an assortment this is certainly wide of, from thin oils that are natural thicker fluids. Its technology this is certainly advanced ensures every fill is consistent, even for items with varying viscosities.

This high-efficiency machine that is filling additionally simple to operate and continue maintaining, that makes it an ideal choice for small and medium-sized businesses. It boils down by having an application this is certainly user-friendly enables you to modify settings and monitor the filling process with ease.

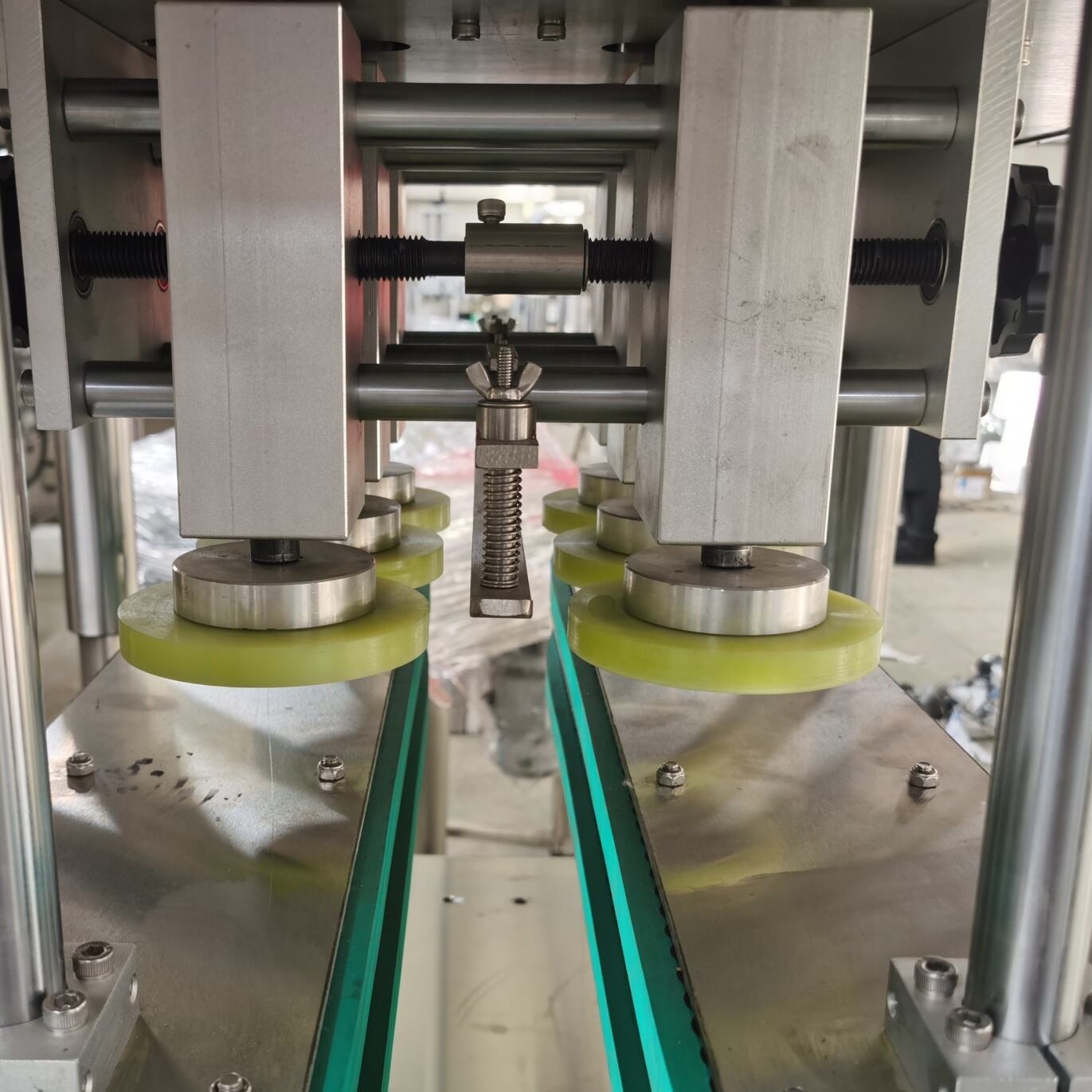

The GF Automatic High Efficiency Viscous Oil Liquid Filling Machine normally designed with security in your head alongside its precision filling capabilities. Its high-quality components and construction that is sturdy therefore it operates efficiently and reliably, in just minimal threat of accidents.