The GF Capping device with 2 nozzles is a product that is amazing every ongoing company owner requires for efficient filling and capping of paste liquids.

This machine was created to immediately fill and cap paste this is certainly different, including creams, creams, along with other thick liquids in jars, bottles, and also other containers of different shapes and sizes. It boils down with advanced functions such as for example a engine this is certainly powerful adjustable filling speed, and nozzle position, which guarantees accurate stuffing and capping.

Using this capping machine, companies can handle amount that easily is high without fretting about spills, waste, and inaccuracies. The GF Capping device with 2 nozzles is perfect for little, moderate, and production that is large-scale. It is efficient, dependable, and simple to work with.

The product was created with top-notch materials that can easily be durable, quite easy to wash, and long-lasting. The 2 nozzles are constructed of stainless steel, that will help to make sure that they shall perhaps not corrode or rust. The machine could be made with a interface that is user-friendly is simple to navigate, making it a simple task to coach brand new staff.

This capping machine is incredibly versatile and that can be utilized for filling and capping numerous forms of products. It works effectively along side kinds of pastes and products that are fluid creams that are including fits in, shampoos, natural oils, and sauces. The GF Capping device is an investment this is certainly very good any company seeking to streamline their manufacturing procedures and guarantee quality products and services.

These devices are compact and calls for really room this is certainly little your workspace. It can be easily moved all over manufacturing area, making it ideal for organizations with limited area. The unit runs seamlessly with just minimal sound and vibration. This makes it a addition this is certainly great any manufacturing line, as it shall maybe not disrupt other operations or cause noise pollution in your workspace.

Factory Wholesale Auto paste liquid filling capping machine 2 nozzles tracking detergent oil bottle filling machine

This Piston tracking filling machine is suitable for filling viscous liquid,such as paste,honey.

jam,sauce,oil,etc.It is equipped with servo motor and only need to enter the certain number to adjust filling range.Compared with other filling machine,this tracking type filling machine can control filling nozzle follow moving bottles during filling work.It reduce production error and improve filling accurately.Widely used in cosmetics,seasonings, washing and care products and other industries.

Featuers:

1.This machine adopts PLC control system, running stably and fast

2. Touch screen control, easy to operate, practical, high efficiency

3. Powerful function, low energy consumption, high degree of automation.

4. Imported electrical components, stable performance, low failure rate

5.Contact with the liquid and exposed places are made of 304 stainless steel

6.. Filling measurement is accurate, filling adjustment is simple and suitable for all kinds of shape bottles.

Product Name |

Automatic bottle detergent filling machine |

Filling nozzles |

2/4/6 |

Production capacity |

2000~5000bph |

Applicable bottle height |

160~360mm,could customized |

Applicable bottle diameter |

Φ50-Φ100,could customized |

Filling Volume |

100~5000ml or customized |

Filling accuracy |

±0.01% |

Overall size (L*W*H)(mm) |

1600*1500*2200 for references |

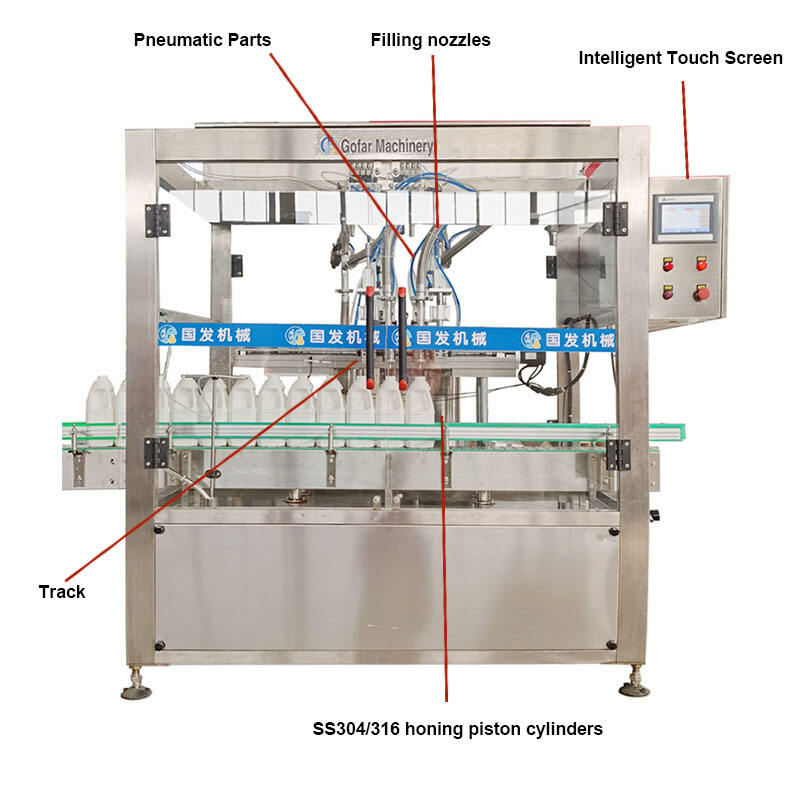

SS304/316 honing piston cylinders with cleaning functions

The cylinder with food grade SUS304/316 materail and the cylinder will be choosed the suitable model according to your bottles volume range.The piston filling volume have two kinds,100ml to 1000ml and 500ml to 5000ml.And the cylinder with cleaning function on the machine,such as for milk,sauce this kind liquid.It will be very convenient to cleaning the machines.

Filling nozzles

Each filling head is equivalent to a stand-alone machine, with automatic filling, which can be opened or closed separately, and has an error correction function. They share a mobile tank, each filling head and tank are connected by a hose, quick-release

excuses, independent control systems and menus, and can be produced separately.

Intelligent Touch Screen

PLC and touch screen control, simple operation and maintenance, automatic counting, no bottle and no filling, one-key cleaning;recipe preservation. The touch screen support adopts a 360-degree rotatable bracket, which is easy to operate, simple and generousin appearance, and strong in practicability, giving the operator a kind of enjoyment at will.

pneumatic Parts

The parts we adopted famous brand to make the whole machine working normally and machine lifespan longer.

It is widely used in the filling of various semi-fluids, pastes, viscous liquid. such as, detergent,shampoo,soap,gel,oil,honey, jams, ketchup, chili sauce, bean paste, shrimp paste, apple sauce, salad dressing, etc.

Q1.How long will take for the delivery of product?10 days for standard model, if machine in stock, will delivery immediately, customized model depend on customer requirements,usually about 20~30 days.

Q2.What's the insurance of after-sale service after purchase?

All our products, will be totally tested by QC department before delivery, with strict quality control process. The product is cost-effective during use, stable and reliable. One year warranty service for all machine, please feel free to contact us if you have any questions.

Q3.When the machine arrives at the work site, is it easy to install?

How to solve the problem of quick installation and use?

All machine model with installation video, to show the installation process more intuitively, and we will provide remote video technical support to solve your doubts and ensure that your installation is correct.

Q4:During the use of the machine, how to get after-sale service?

We have professional foreign installation and commissioning engineers, which have many years of experience in foreign debugging with deeply recognized by customers. We will provide on-site installation and commissioning services for foreign customers, and we will guide your workers directly.

Q5:Will the accessories change frequently with machine?

The service life of the accessories is related to the daily maintenance. When ordering, we will give you free wearing parts and provide you with daily maintenance strategies.