Έχετε ποτέ σκεφτεί πώς αυτή η μπούτιλα σόδα φτάνει εκεί στο ράφι του σουπερμάρκετ της γειτονιάς σας; Τώρα, μια κρίσιμη φάση αυτού του ολοκλήρου διεργασιακού κύκλου είναι η γραμμή μπουτιλάρισματος. Κάθε μπούτιλα γεμίζεται, σφραγιστεί και ετικετολογείται από ένα σύνολο μηχανών που ονομάζονται γραμμή μπουτιλάρισματος. Jim Gandy/Wikimedia Εφαρμόστε τις πιο νεoteric τεχνολογικές εξελίξεις, και θα δείτε τις βιομηχανικές διεργασίες σας μετατροπισμένες ως προς αποτελεσματικότητα και αποδοτικότητα.

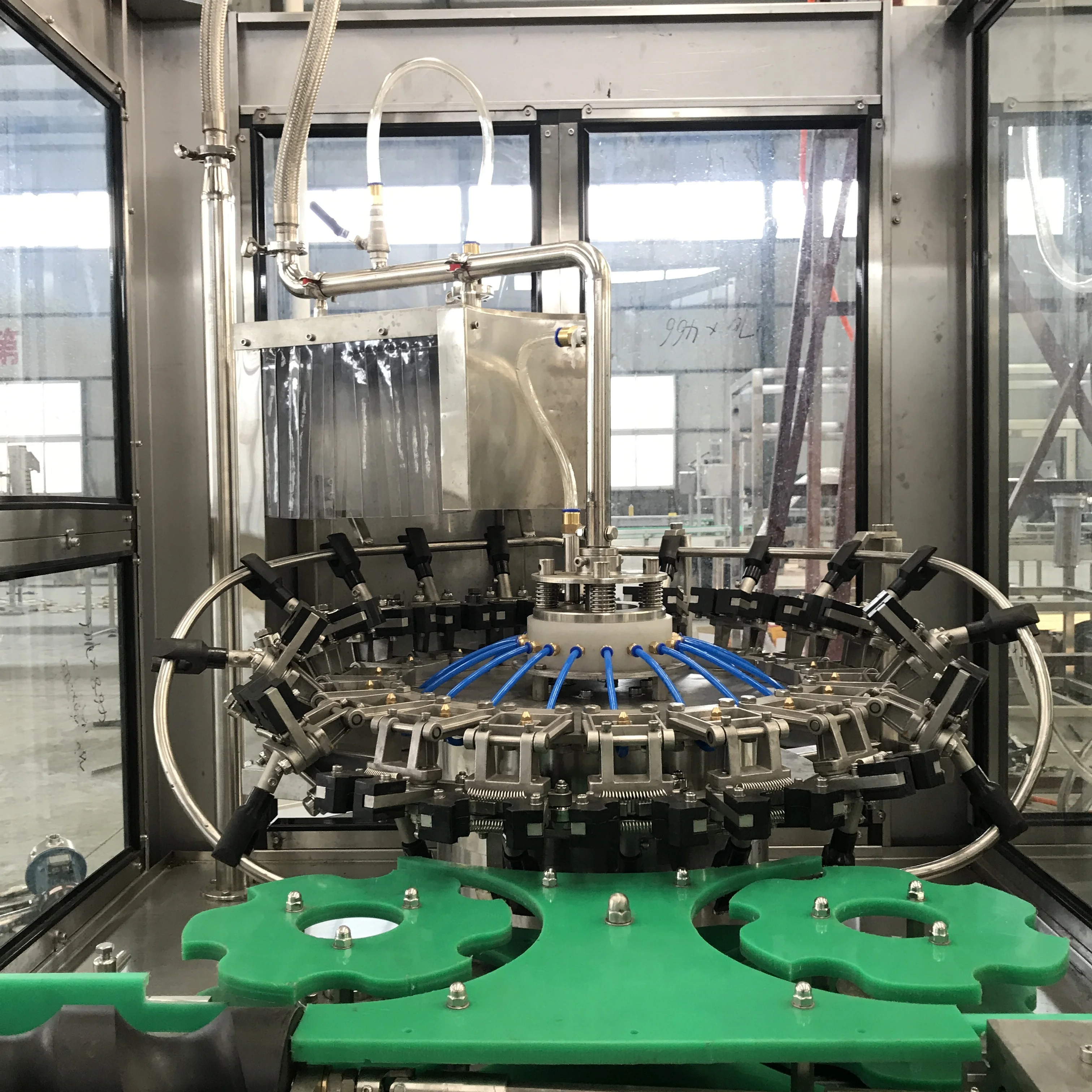

Τεχνολογικά, οι γραμμές μπουτιλάρισματος έχουν εξελιχθεί έτσι ώστε πολλές από τις φάσεις της γραμμής να έχουν αυτοματοποιηθεί, που προηγουμένως επιτελούνταν χειροκίνητα. Για παράδειγμα, η εφαρμογή καπάκιων σε μπούτιλα ήταν ένα χειροκίνητο διαδικαστικό που επιτελούσαν πολλοί εργάτες για πολλά χρόνια. Ωστόσο, όταν οι μηχανές άρχισαν να εκτελούν αυτή τη διαδικασία, έγινε πολύ ευκολότερη για όλους, μειώθηκαν οι ανθρώπινες απαιτήσεις και έγινε η διαδικασία γρηγορότερη. Αυτό σημαίνει ότι τα διαθέσιμα μπούτιλα ανά ώρα γεμίζουν σε μικρότερο χρονικό διάστημα, κάνοντας τη λειτουργία πιο κερδοφόρα.

Βελτιώνοντας την αποτελεσματικότητα και την ποιότητα της διαδικασίας παραγωγής. Υπάρχουν πολλοί τρόποι για να μειωθούν οι εξόδοι, να αυξηθεί η αποτελεσματικότητα ή να βελτιωθεί η ποιότητα ενός προϊόντος στις προσπάθειες γύρω από τις γραμμές μεταποίησης σε φλιώτα.

Ένας τρόπος για να αυξηθεί η αποτελεσματικότητα είναι με τη χρήση μηχανών που είναι προσαρμοσμένες για την διάταξη των φλιών σας. Εκτός από τη μείωση των αποβλήτων, αυτές οι προσαρμογές οδηγούν επίσης στη μείωση των λαθών. Αξίζει επίσης να αναφερθεί, μέχρι τον βαθμό που έχετε έλεγχο, να διατηρείτε τις μηχανές σας καλά και σε κορυφαία κατάσταση λειτουργίας. Με την τήρηση αυτής της γενικής διατήρησης και καθαρισμού, βοηθάτε να προλάβετε τις ανομαλίες λειτουργίας, που με τη σειρά τους εξασφαλίζουν την αποτελεσματική λειτουργία της γραμμής μεταποίησης σας.

Για να εγγυηθείτε την υψηλή ποιότητα του προϊόντος, πρέπει να έχετε μια πολύ καθαρή/στεριλή περιβάνθωση κατά μήκος και γύρω από τη γραμμή διατροφοδόσεως. Ακόμη και ένας κύκλος παραγωγής προϊόντος μπορεί να θεωρηθεί εντελώς παρακμασμένος αν υποβληθεί σε μολύνση, έτσι η καθαρισμός πρέπει να διατηρεί την απολύτως αυστηρή διακριτικότητα. Επιπλέον, για να εγγυηθείτε το υψηλότερο επίπεδο ποιότητας και ακεραιότητας του προϊόντος, πρέπει να χρησιμοποιείτε υψηλής ποιότητας συστατικά και μηχανήματα.

Η γραμμή διατροφοδόσεως μας κάνει πιο εύκολη την κατανόηση των λεπτομερειών της διατροφοδόσεως ποτών. Το επαναστατικό μας σύστημα περιλαμβάνει μια σειρά προνιών και έχει σχεδιαστεί για τη δημιουργία υψηλής ποιότητας ποτών που είναι εξαρτήσει των γεύσεων των πελατών σας.

Ελαχιστοποιεί σημαντικά την ανθρώπινη ενδιάμεση εντοπισμένη και εγγυάται αποτελεσματικότητα και παραγωγικότητα κατά μήκος της αυτοματοποιημένης γραμμής διατροφοδόσεως. Η φιλική προς τον χρήστη διεπαφή και οι ελέγχοι της κάνουν εύκολη τη λειτουργία ακόμη και για τον λιγότερο εμπειρογνώμονα χρήστη.

είναι ειδικοί λύσεις συσκευασίας υγρών λικέρ, νερού, ελαίου, πλύντρου, υγρού χαρτιού, κ.λπ. Δέκα υψηλά εξειδικευμένοι μηχανικοί γραμμής συσκευασίας έχουν περισσότερα από 15 χρόνια εμπειρίας στον τομέα της συσκευασίας. Μπορούμε να προσαρμόσουμε μηχανήματα σύμφωνα με τις απαιτήσεις των πελατών. Με ειδική υπηρεσία μετά την πώληση, μπορούμε να βοηθήσουμε τους πελάτες να επιλύσουν προβλήματα άμεσα.

χρησιμοποιείτε βιώσιμα υλικά για την θεμέλιο του εξοπλισμού καθώς και ανθρακωτό αδρανές χάλκινο 304/316 για τα στομιά πλήρωσης. Εκτός από το ανθρακωτό αδρανές χάλκινο, συνεργάζεστε και με διάσημες μάρκες όπως Siemens, Schneider, Omron, Autonics, Mitsubishi, κλπ. Θα δοκιμάσετε το μηχάνημα πριν το συσκευαστεί και θα παρέχετε τις οδηγίες και τα ανταλλακτικά για τη γραμμή κανέρωσης.

Ως εταιρεία με χρόνια εμπειρίας στις γραμμές κανέρωσης και τις λύσεις συσκευασίας, θα προσφέρουμε στους πελάτες τη καλύτερη λύση σύμφωνα με τις απαιτήσεις και τον προϋπολογισμό τους. Διαφορετικός προϋπολογισμός θα έχει διαφορετικές λύσεις. Ο μηχανικός μπορεί να βοηθήσει τον πελάτη να εξοικονομήσει χρήματα και να βελτιώσει την εργασιακή αποτελεσματικότητα.

μπορεί να παρέχει λύσεις γραμμής κανέρωσης που να καλύπτουν τις διάφορες ανάγκες των πελατών.Ένα εμπειρογνώμονα ομάδα θα αναπτύξει το σχέδιο σύμφωνα με τις απαιτήσεις.