Companies must be correct when packaging products. They are there to ensure customers get the amount of product they need without overpaying or wasting materials. That is the reason why most industries make use of weighing and filling equipment.

Weighing And Filling Machines - Weighing and filling machines are apparatus that can weigh products quickly y just putting on a scale, with extreme precision. This made these machines even faster, thanks to modern technology. In seconds, they were able to weigh out dozen of products and package angrily away.

For e.g. The modern filling & weighing machine will use sensors to measure weights of products With such features, it can detect changes in weights that are so small adjusting to the exact type of products weigh without error

Automated Weighing and Filling Machine - Key Advantages For A Business It saves time: the machine can weigh and pack products automatically. Second, it cuts costs by weighing and packaging products accurately (less waste). Third, weighing to same products each time increases product consistency.

An automated weighing and filling system - Starting a plant with weight filler in India It takes less time to package, improves packaging and decreases errors. Helps In The Smooth Running Of Business: Using this system a business can function effectively and efficiently.

Businesses reduce waste and costs by using automated weighing/filling equipment. This reduces wastage and helps to avoid under-filling or over-filling which will cost you customers.

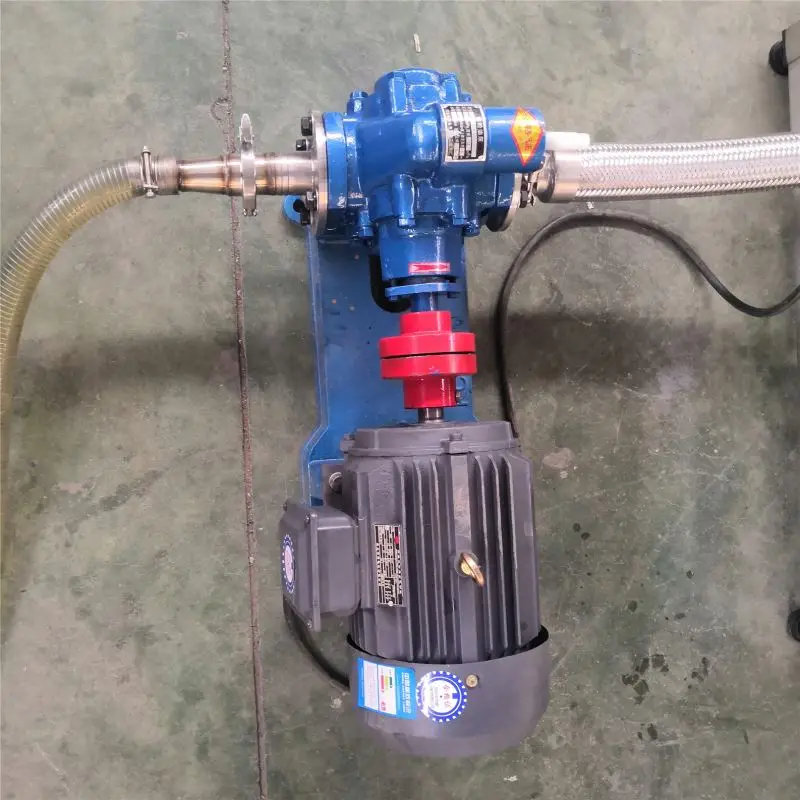

The only way to achieve this is by investing in a cutting-edge weighing and filling machine, which can completely revolutionize your packaging process. These systems work with great accuracy and offer high efficiency, so they are well suited for large scale companies. They come with more advanced perks such as touch screen, and automation controls so you can fine tune it to your liking.

are professional liquid packaging solution expert liquor,water,oil,detergent,liquid shampoo,etc. Ten highly weighing and filling machineengineers have more that 15 years experience in field of packaging. can customize machines according to customer's requirements. With professional after sales service, we can help customers solve problems promptly.

equipment's base made of sturdy materials. weighing and filling machinenozzles have been made from food grade stainless steel. Besides the stainless steel, also cooperate with famous brand like Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. will test the equipment before packaging it, and then give buyers instruction manuals as well as spares.

As company with years weighing and filling machinepackaging solutions,we will provide customers with best solution according customer's requirements budget. Different budget will different solutions. engineer can assist client save money improve working efficiency.

As professional business, can provide turnkey solutions satisfy different customer specifications. weighing and filling machinemust tell us his requirement,his workshop layout,bottle cap photos,etc.expert team will create layout based on the buyer's request.Feel comfortable contacting our sales staff if require a turnkey line solution liquids packaging.