Did you realize that there is a particular machine designed to fill bottles and containers with liquids? Well, this wonderful equipment is none other than a pump filling machine. Factories and warehouses can benefit from this as it helps them work at a faster pace with more productivity. Instead of manually filling every bottle -- a process so tedious that it can take minutes to complete an entire one!

Filling up bottles or containers one by one can be a very time consuming activity if you have many to process. It may seem that it should be done very quickly, but do not rush, as you can splash the solution and lose some of itscosity. Not only is this messy, but it can also end up costing your business some $. Plus, you can fill hundreds of bottles in a matter of minutes with a pump filling machine. And the best part is, there will be no mess after it all in the end — a big win for any business!!

You can pick the pump useful finisher machine from that also with dimension and type depending on what is suited to your liquid. See, some liquid are thick and few liquids being thin as well. Another pro is the machine can be adjusted to work great with whatever you are filling. Then you get to choose how many nozzles should be installed there, and even pick additional functions that will make your production line run better. Your business can grow or change over time, no problem! You can, of course, add or take away features from your pump filling machine as required to fit the changing needs.

However, one issue with filling by hand is spillage. If you pour liquid using your hand in the bottle or container then it may spill and now we have to clean that. That can get very annoying, especially if you have quite a few containers to fill. It could be worse if you do it in a hurry and even spill more, thus creating an even bigger mess.

But no more wasting liquid or time when you use a filling machine with pump. There are as many versions of bottling machines as there are types of food to put in them, but the basic premise is: all liquid which must go into a container should do so via automation without creating chaos. Which means you could perform better! You can also program the machine to fill the containers at a consistent pace, whether slowly or fast, for an added peace of mind knowing that everything is regular and expected. This saves you time and also allows your products to be consistently high quality.

All you have to do is configure the correct pump and probe type for your liquid, with a fill machine that uses this technology. Just set the settings according to the thickness of your liquid, and begin filling containers as they travel along production line. Each container now gets the correct amount of liquid automatically dosed directly from this machine without any hassle. This is less stressful for you and your workers that any individual can concentrate on other important works.

No organization ever refuses to earn more money and one of the things that will bring them closer is a pump filling machine. The bottle and container can be filled in less time than at a manual level by using this machine. This makes it easier and faster for you to create more products, put them on the shelves.

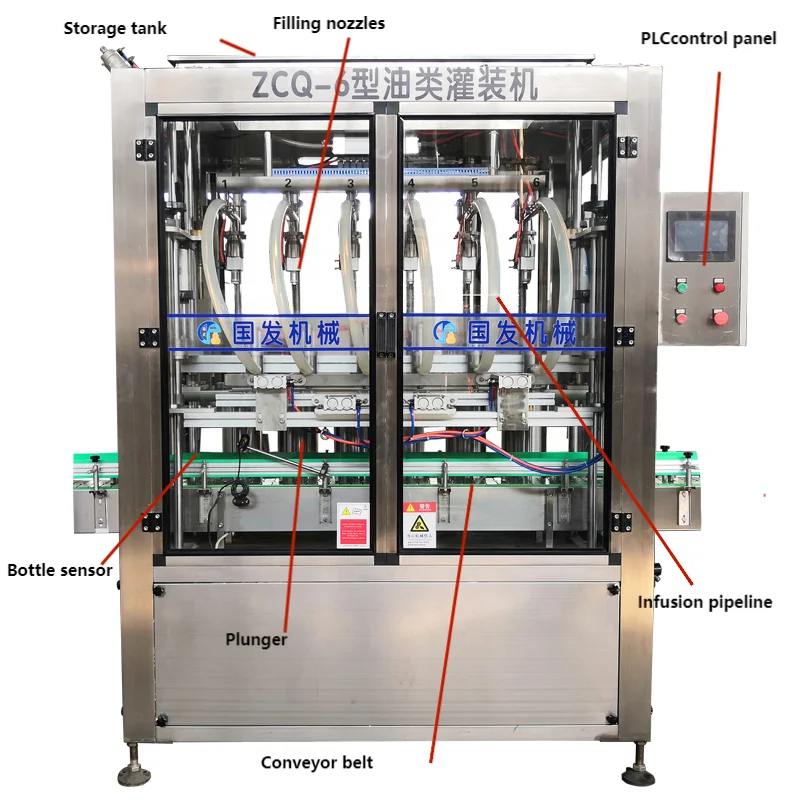

equipment's base constructed from sturdy materials the filling nozzles made food-grade stainless steel. Besides stainless steel, we also cooperate with famous brand like Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. Prior to shipping, will analyze the machine and provide manuals and spare parts for the pump filling machine.

offer turnkey solutions meet the various needs customers. experienced team will develop layout pump filling machinewith your requirements.

are professional liquid packaging solution expert for liquor,water,oil,detergent,liquid pump filling machine,etc. 10 experienced designers and developers with over 15 years of experience in packaging field. We able to customize the machines according to the specifications the customer. provide professional after-sales services help our customers resolve issues quickly.

We'll recommend best packaging solution customers accordance with their budget needs. Every budget has own solutions. engineer can assist customer reduce costs increase pump filling machineefficiency.