If you are making beverages such as juice, soda or bottled water, chances are that like many others in this segment of the food industry customer service and efficiency is high on your list. People have high standards for their drinks, they want them fast and good. A bottle filling machine can assist in this by expediting the process of packaging product into bottles, therefore saving time and money.

Bottle filling is the process of using a bottling machine to automatically fill bottles with liquids, viscous products or gases. But now, you do not have to stuff each bottle on hand. Imagine how many hours it would take to fill hundreds or thousands of bottles one by one! A bottle filler can be used to fill up many bottles in a single hour, block-wise and extensive the draying is. Which will give you more time for attend to other important areas of your business!

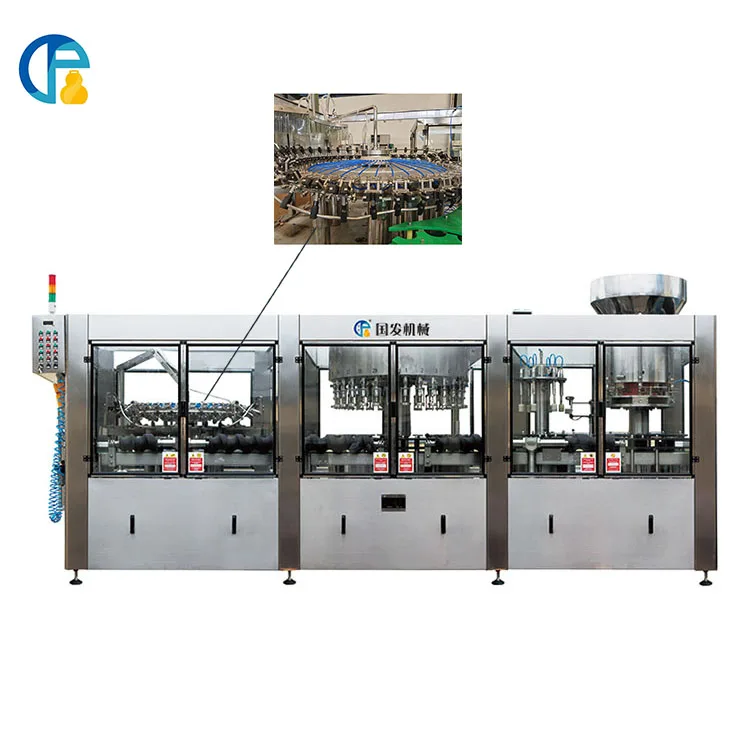

Whatever kind of drink you intend to make, there is a bottling machine that will get it just right. Then, there are numerous machines that can fill bottles of different shapes and sizes! That's the beauty of it. It is machine specific, for example, they have some machines exclusively JUST for the soda-machine or other only for still beverage like juice and water.

Well, the good news is that there are also machines for serving both types of drinks! This also means that there will likely be a good bottling machine to cater exactly for the drinks you are selling. When you have this much choice, you can choose the best one for your business and get that sewing machine to keep on working away in no time at all.

That means you can make a greater number of bottles faster than most would normally do so, meaning you are better able to meet demand (and this ultimately helps with monetization). If you can speed up bottling, there may be a consumer demand to fill more bottles faster so customers get their drinks when they ask for them. Furthermore, collecting hundreds and even thousands of bottles at bars wastes human labor effort for filling those bottle positions. You will be able to save a good amount of your worker costs and thereby increase the profits!

But it also ensures that you maintain the same quality in your drinks. And when you fill bottles by hand, there are human errors. Occasionally a bottle might get underfilled — presenting its contents differently. And unhappy customers that anticipate the same level of quality within every bottle.

However, with a bottling machine it will ensure each bottle receives the same amount of liquid every time! This enables you to maintain consistency in every bottle your produce which is vital for creating a strong brand perception. If customers know they can rely on good quality in your drinks, it will give them reasons to keep coming back. Not to mention happy customers are more likely to refer you moves their friends and family, increasing your business even further.

are professional liquid packaging solution expert for liquor,water,oil,detergent,liquid shampoo,etc. Ten liquid bottling machineengineers in design development with over 15 years of experience in the packaging industry. can tailor the machines satisfy the specifications of customer. offer professional after-sales service that will assist customers solve their problems within a short time.

We firm with extensive expertise packaging solutions, provide customer best solution meet the requirements customer and budget. Each liquid bottling machinewill require solutions. engineer can assist the customer saving money while also increasing efficiency of project.

can offer turnkey solutions satisfy diverse customer liquid bottling machine. experienced team will develop layout that based on requirements.

base of equipment made of sturdy materials, the filling nozzles are made with stainless steel that is food liquid bottling machine. Besides stainless steel, also cooperate with famous brand Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. Before packing,we will debug machine and supply manuals and spare parts for the buyer.