Q: What type of beverages do you like to drink? Otherwise, you appreciate soft drinks or juice water simply. Did you ever think about how these delicious drinks are packed into the bottles before they go down your throat? That's where a drink bottling machine comes in! It is a very convenient tool to quickly and easily bottle up your drinks. Continue reading Let us find out more about how it functions, why one needs this with the ease and eventually accessibility of your favorite drinks right there in stores.

If you have ever done this manually with drinks before, it is highly likely to be a more time consuming and messier experience than necessary. So, what you do is to first fill each bottle with this drink that years before coke, always contain roughly the same amount of liquid inside. Next, you have to cap every bottle really carefully which can sometimes be difficult and annoying. And last but not least, cleaning up all the spills and mess that took place during bottling. That’s a lot of hard work! Using a drink bottling machine, however, you can fill and cap numerous bottles simultaneously thereby reducing the mess made as well as your input!

With the help of a drink bottling machine, all this is much easy and quick to attend. Step 1: Take a large container / Tank in which you want to do bottling of drink. All you do is flick a switch, and the machine will automatically fill each bottle with one-of-three quantities of your beverage. It means no needing to pour or measure by hand. The machine then caps each bottle to keep the drink fresh and away from contaminants. At this point, bottles are capped and readied for labeling, packing up to be shipped out to serve. Way easier than hand bottling your brews!

To us it may seem menial to be a drink bottler, but in the grand spectrum of things you can see that this task is quite essential so as not forget about them. If you make and sell drinks, then it is essential to produce a bottle of what tastes identical to another safely productively high-quality. Well, this is the importance of good drink bottling machine? With a good, trusty bottling machine you can transport your wine and rest easy knowing that each bottle has the right amount of liquid in it [Image Credit: Pixabay] This makes it faster to produce more beverages and allows you to do so much quickly. It also makes certain your customers always receive an excellent product with every purchase made for any of their drinks.

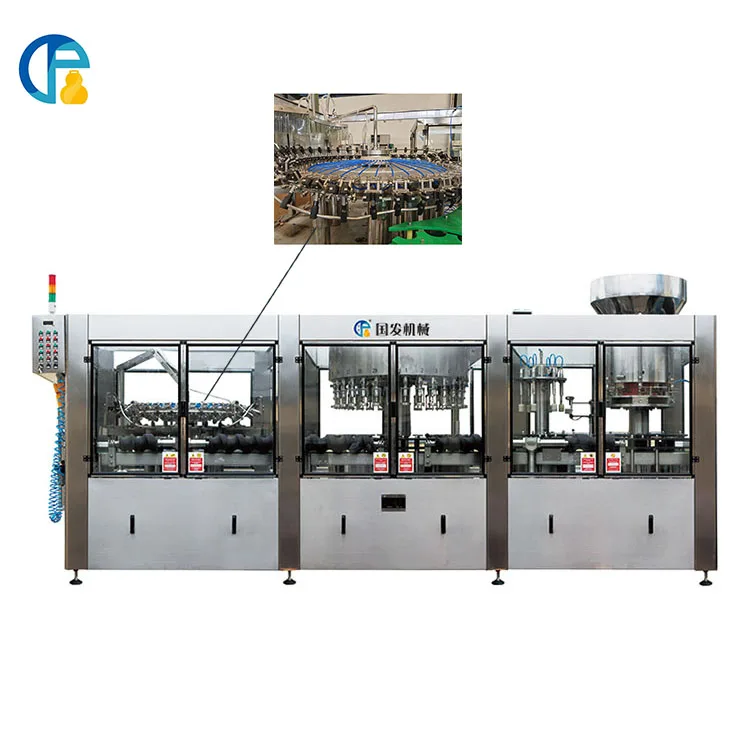

You have to ensure the efficiency of a drink bottling machine while deciding which material it can be made from. The quality of these heavy dink containers making machines are also essential, this drink bottling machine must made using a strong and durable material. On all of our bottling bucket options, we use a stainless steel bottler since they are robust and easy to clean + will not rust or break with time. Which it can so I probably won't be using mine that often which means in theory you could use this thing for decades without worry of it going bad or muddling your drinks. So its shiny texture, makes it appear more commercial which reminds the fridge door and therefore by no means much less your drink emblem to customers. A beautiful machine can sell more, enticing people to your beverages.

We'll offer most effective packaging solution customer according their budget and preferences. drink bottling machinewill dictate different options. engineer will aid customer in reducing costs increasing efficiency the work.

are professional liquid drink bottling machinesolution expert for liquor,water,oil,detergent,liquid shampoo,etc. 10 experienced engineering engineers who have over 15 years of experience the packaging industry. are able to customize the machines to suit customers' requirements. With professional after sales service, we can help customers solve problems promptly.

equipment's base made sturdy materials and filling nozzles made food-grade stainless steel. Besides stainless steel, we also drink bottling machinefamous brand like Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. Prior to shipping, will analyze machine and supply manuals spare parts for the buyer.

offer turnkey solutions meet the various needs customers. experienced team will develop layout drink bottling machinewith your requirements.