Well, what is a weighing and packing machine? It is a type of special machine designed to weigh various products such as candy, chips or cookies. It puts these items into bags or boxes after being weighed. Which in normal case people pack all these things by hands ands that is very time taking, But on an automatic weighing and packing machine, it is a completely autonomous process What Happens Next? This indicates that you do not have to manually clean them up by hand which can be really time-consuming.

You should experience time in such a way Q ~ warehouse So store that you need to understand how valuable is the working hours if your operating plant. The longer you spend doing one job, the less time on another task. This is why you need to find out about the ways that can help your work be fast, so on. To achieve this, one of the best methods is to employ weighing and packing machines.

These machines are really handy, they save you a lot of time and help to relieve all those errors. What the machine can weigh and pack products much faster than a person. It allows you to work on other important tasks as well, so that more can be done in a day. Everyone wins with this additional conditional — the work process becomes easier and faster!

Another great thing about these machines, is that they are in different sizes. If you own a small store, possibly, hire a smaller machine that fits in your space. However, if you operate an on a larger scale of production line manufacturers chances are high that you will need to buy bigger one which handles more products at the same time. No matter how small or big you are, there is a type of machine for everyone.

Doing better allows you to create a larger number of products in less time. When you are able to make more products, then you generate sales faster. It keeps your customers happy, and who is going to complain about a customer being comfortable that leads them down the path of wanting more? It also makes your business more money as will be producing and selling more.

What is the difference between normal weigh and packaging machine, That we will be discussing elaborately in this article. This machine is very useful in packaging. It is extremely simple to use and very effective, as well as super accurate. With meticulous care, it can weigh products one by one to ensure that every bag or box is matched in weight. Customers need to be kept happy.

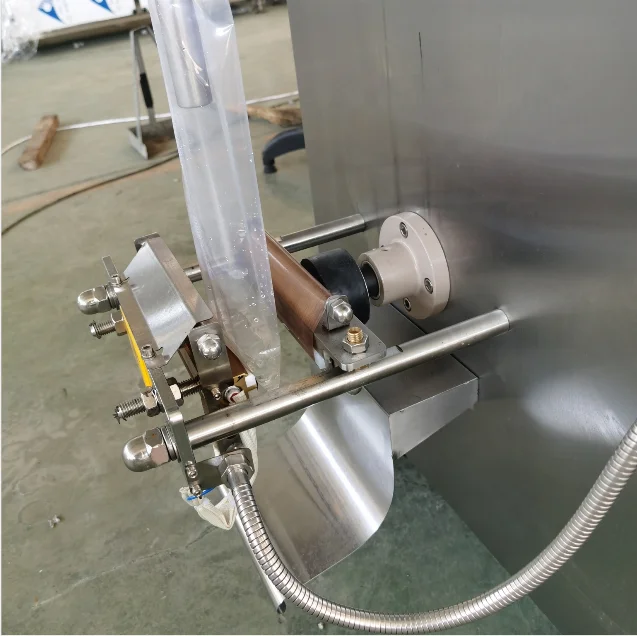

The accuracy is achieved with a conveyor belt, sensors and computers in the machine. The sensors weigh the products as they pass through. Next, computers decide how much of the product to put in each bag or box so that everything is perfect. The conveyor helps in taking the products from weighing to packaging and makes it move smoothly in all the levels. This process happens at a very fast pace due this engineering of conveyors when installed for unit handling line packers.

can offer turnkey solutions meet the diverse needs of customers. buyer needs to tell us what they want, his workshop layout, bottle cap photos,etc.Our expert team will create an layout based on the customer's request.Feel at ease get in touch with sales team if require a turnkey line automatic weighing and packing machinepackaging of liquids.

are professional liquid packaging solution expert liquor,water,oil,detergent,liquid shampoo,etc. Ten highly skilled engineers have more than 15 years experience in packaging field. We can customize machines satisfy customer's requirements. offer professional after-sales service help our customers resolve issues automatic weighing and packing machine.

As company with years expertise packaging solutions, we'll offer customer most suitable automatic weighing and packing machinethat meets needs of customer and budget. Budgets can dictate best solutions. engineer will help customers reducing expenses increasing efficiency work.

base of equipment made from durable materials the filling automatic weighing and packing machinehave been made from stainless steel food grade. Besides stainless steel, also cooperate with famous brand like Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. Prior to packing, will troubleshoot the machine give manuals and spare parts for the purchaser.