Do you like drinking juice? Juice is a delicious drink that people all over enjoy drinking! Ever wondered how juice is made? It’s interesting! Then we produce a juice from this — squeeze the fruit / veg and then discard of that remainness (pomace) []. This may possibly include delicious fruits such as oranges, apples or grapes. In order to be sold in stores the juice must thenine, s- bottledology) filled and packaged into bottles; cartons or cans. This entire process can be time consuming and laborious if people will do it manually. However, there is a method to speed up and simplify the process for everyone — using machinery such as an automatic juice-packing machine if you want!

The reason a juice packing machine is specifically developed to ease this process. The juice filler and capper: it will fill jugs & bottles of juice with out the necessity to hire anybody! This works out to the machine taking on board work of so many people in a relatively stunning span of time. This also benefits juice manufacturers by allowing them to make more juice at the same time satisfy customer demand.

Here the juicing packing machines that have been introduced recently and they include high technicalities to ensure juice are packed in a considerable speed more than ever before. 2# Automatic juice packing machine The automatic juice packaging machines can pack the many packs of juices within very less time. That will help you work more efficiently and save time plus money in the production of your juice.

The new technology also ensures a tight juicing process without any kind of spillages or leakag A total game-changing development, as it offers the possibility of keeping fresh liquid…fresh and great for consumers. No one else sees the product, only experience it when they do get their juice. Since customers pay good money to buy this premium grade pressed raw cold-pressed that will make them happy in every sip of something tasty and wholesome so you better pack right because a satisfied customer always comes back!

So do you want to way of making juice, easily in no time. Thank you can have a juice filling and packing machine accomplished that for later UPROPERTY, please With the machine fill and pack of juice are executed back to back providing a ceaseless generation of juice close by. Which is ideally what you want to catch, people buying things. You never know when demand can be high, and you want to service it.

Or we can say juice filling and packing machine is too much user friendly as well. It is nothing very difficult and can be ran without any special skills or training. It does require a bit of an initial setup, but once it is going the machine will do all its work. So you can spend the time thinking about what new juice flavors to make, or how best grow your business.

If nothing else, you will be able to afford the best juice packing machine and make more money elsewhere. Number one it can help you save on labor cost and this is because now, fewer people are need to assist in packing the juice. The second is, It will help you to work faster which allows it to deliver more juice in less time. You can sell more juice = improved margin. Third, it can improve your juice which will in return keep customers satisfied and buying from you.

We'll recommend best packaging solution customers based budget needs. Every budget has its solutions. engineer can automatic juice packing machinecustomer saving money while also increasing efficiency the work.

can offer turnkey solutions satisfy diverse customer automatic juice packing machine. experienced team will develop layout that based on requirements.

are professional liquid packaging solution expert for liquor,water,oil,detergent,liquid automatic juice packing machine,etc. 10 experienced designers and developers with over 15 years of experience in packaging field. We able to customize the machines according to the specifications the customer. provide professional after-sales services help our customers resolve issues quickly.

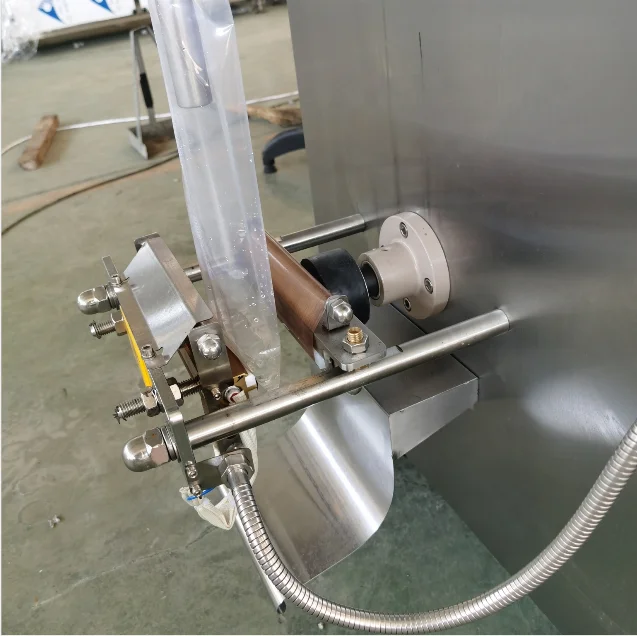

equipment's base made of sturdy materials. automatic juice packing machinenozzles have been made from food grade stainless steel. Besides the stainless steel, also cooperate with famous brand like Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. will test the equipment before packaging it, and then give buyers instruction manuals as well as spares.